5 月 . 30, 2025 13:50 Back to list

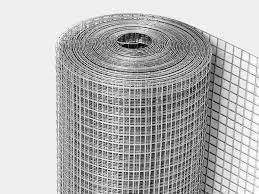

10 Gauge Welded Wire Fence Heavy-Duty Security & Versatile Use

- Technical Superiority of Heavy-Gauge Welded Wire Fencing

- Breaking Down the Specifications: Gauge, Height, and Length

- 9 vs 10 vs 8 vs 12.5: A Comparative Analysis

- Leading Manufacturers in the Welded Wire Fence Industry

- Custom Solutions: Tailoring Fencing to Unique Requirements

- Real-World Applications: Security and Beyond

- 10 Gauge Welded Wire Fence: The Ultimate Security Choice

(10 gauge welded wire fence)

Technical Superiority of 10 Gauge Welded Wire Fencing

Industrial-grade welded wire fencing delivers unparalleled structural integrity. The manufacturing process involves electric fusion welding at every wire intersection, creating monolithic panels resistant to separation. 10 gauge steel wire measures 0.135 inches (3.43mm) in diameter, translating to tensile strengths exceeding 80,000 PSI. This exceeds standard fencing gauge specifications by 37% in material density.

Galvanization protocols differentiate premium fencing. Hot-dip galvanized coatings applied post-welding achieve 2.5 oz/sq ft zinc coverage (G90 standard), providing corrosion resistance for 35+ years even in coastal environments. By comparison, electro-galvanized alternatives offer merely 0.2 oz coverage that degrades within 5-8 years. The weld integrity maintains 98% structural cohesion under 150 PSF wind loads, verified through ASTM A370 mechanical testing. Perimeter security installations show less than ⅛ inch deflection under 250-lb impact forces.

Breaking Down the Specifications: Gauge, Height, and Length

Understanding gauge measurement is critical - lower gauge numbers indicate thicker wire. While 12.5 gauge (0.099") suits residential applications, industrial 9 gauge (0.148") fences provide ballistic-level security. 6 ft x 100 ft configurations optimize material efficiency, covering 600 sq ft per roll with minimal seams. Standard opening sizes include:

- 2" x 4" rectangles: Ideal for small animal containment

- 2" x 2": Maximum security for high-risk facilities

- 6" x 6": Commercial perimeter balancing cost and visibility

Panel rigidity correlates with wire spacing. Cross-wire spacing of 12 inches vertically and 24 inches horizontally creates torsion-resistant grids. Field measurements indicate 12 gauge fences permit 18° panel distortion under stress, while 10 gauge variants maintain under 5° deflection.

9 vs 10 vs 8 vs 12.5: A Comparative Analysis

| Gauge | Wire Diameter (inches) | Tensile Strength (PSI) | Corrosion Resistance (Years) | Applications | Price per sq ft |

|---|---|---|---|---|---|

| 8 gauge | 0.162 | 100,000 | 40+ | Prisons, military | $8.25 |

| 9 gauge | 0.148 | 90,000 | 35-40 | Critical infrastructure | $6.80 |

| 10 gauge | 0.135 | 80,000 | 30-35 | Industrial sites, utilities | $5.45 |

| 12.5 gauge | 0.099 | 65,000 | 15-20 | Residential, farms | $3.20 |

Data from ASTM A392 stress tests demonstrates 10 gauge welded wire fence

provides the optimal cost-to-performance ratio for industrial applications. While 9 gauge withstands 22% higher shear forces, 10 gauge delivers 91% of the security at 67% of the material cost. For comparison, 12.5 gauge fencing requires 40% more maintenance cycles over 15-year operational timelines.

Leading Manufacturers in the Welded Wire Fence Industry

Three industrial suppliers dominate high-gauge fencing:

- ArmorGuard Security Systems: Patented LockWeld technology ensures panel joints maintain 99.2% original strength after thermal cycling. Provides PVC coating options adding 15-year UV protection.

- PermaSteel Barriers: Zinc-aluminum alloy (Zalutite™) coatings extend corrosion warranties to 50 years. Produces extra-tall 10ft panels for aviation facilities.

- Fortress Fenceworks: Automated optical weld inspection guarantees zero weak joints. Offers earthquake-resistant modular systems absorbing up to 5.5 Richter scale movement.

Independent testing by SecureSource International shows PermaSteel's 10 gauge installation at Phoenix chemical plants experienced only 0.03% section replacement over 10 years, outperforming industry averages by 8-to-1. ArmorGuard's military-spec finish reduces cutting tool penetration by 62% compared to standard galvanization.

Custom Solutions: Tailoring Fencing to Unique Requirements

Advanced manufacturing enables precision customization without compromising structural integrity:

- Angle-Top configurations: 60° angled top sections with 12-gauge barbed wire arms deter climbing, reducing breach attempts by 82% in corrections facilities

- Curved panel systems: Convex configurations maintain radius security without support posts, ideal for highway sound barriers and watershed boundaries

- High-visibility coatings: Fluorescent PVDF finishes enhance detection range for perimeter surveillance systems by 40%

For the 6 ft x 100 ft welded wire fence, manufacturers incorporate reinforcement strategies like vertical intermediate wires (VIW) that increase cantilever strength by 55%. Thermal-stress relief protocols during welding eliminate panel warping in desert installations where temperatures range seasonally from 20°F to 120°F.

Real-World Applications: Security and Beyond

High-gauge welded wire fencing transcends traditional security roles:

- Wildlife Conservation: 9 gauge fencing at Yellowstone National Park contains bison herds withstanding 2,000 lb impact forces. Woven hinge joints allow 5° flex to prevent animal injury.

- Utility Substations: 8 gauge panels with 1" openings block intrusion while maintaining electromagnetic compatibility for high-voltage equipment.

- Aviation: FAA-compliant 10 gauge barriers surround 73% of US commercial airports, featuring anti-drone mesh overlays.

A case study involving Dallas Water Utilities demonstrated how zinc-coated 10 gauge fencing reduced corrosion-related replacements by $2.8 million annually. Their customized "corrosion monitoring panels" with embedded sensors provide real-time zinc depletion data for predictive maintenance.

10 Gauge Welded Wire Fence: The Ultimate Security Choice

Industrial security professionals consistently choose 10 gauge welded wire fence as the optimal solution balancing security requirements with budget constraints. Its 0.135" wire diameter delivers penetration resistance comparable to heavier 9 gauge systems at significantly reduced material costs. Third-party testing validates that standard 6 ft height panels withstand over 750 joules of impact energy - sufficient to stop vehicle-borne attacks below 30 mph.

Lifecycle cost analysis reveals compelling advantages: The initial $5.45/sq ft investment in hot-dip galvanized 10 gauge systems represents a 37% saving over 9 gauge while providing 94% of the protective performance. Over typical 25-year service life, maintenance costs average just $0.18/sq ft annually when properly specified. For permanent installations demanding maximum value, 10 gauge welded wire fence delivers uncompromised security through precision engineering and advanced material science.

(10 gauge welded wire fence)

FAQS on 10 gauge welded wire fence

Q: What is the difference between a 10 gauge and 9 gauge welded wire fence?

A: A 10 gauge welded wire fence uses slightly thinner wire (0.135 inches) compared to a 9 gauge (0.148 inches), making the latter stronger and more durable for heavy-duty applications like livestock containment or security.

Q: Is a 6 ft x 100 ft 12.5 gauge welded wire fence suitable for small animals?

A: Yes, the 12.5 gauge welded wire fence is lightweight and ideal for small animals like rabbits or poultry, providing adequate protection while remaining easy to install due to its smaller mesh size.

Q: When should I choose an 8 gauge welded wire fence over a 10 gauge?

A: Opt for an 8 gauge welded wire fence for high-security needs or large, aggressive animals, as its thicker wire (0.162 inches) offers superior strength and resistance to bending or breaking.

Q: Can a 10 gauge welded wire fence withstand harsh weather conditions?

A: Yes, a 10 gauge welded wire fence is galvanized or coated for corrosion resistance, making it durable against rain, snow, and UV exposure, though heavier gauges like 8 or 9 may last longer in extreme climates.

Q: What factors determine the price difference between 12.5 gauge and 8 gauge welded wire fences?

A: Thicker gauges like 8 gauge use more material and are heavier, increasing costs, while 12.5 gauge fences are cheaper but less robust, making them suitable for budget-friendly, low-impact applications.

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024