2 月 . 10, 2025 11:36 Back to list

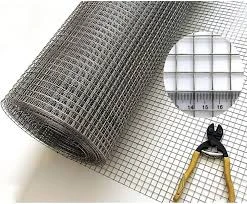

10 gauge welded wire mesh

When it comes to securing your property or ensuring the safety of your livestock, you need a solution that is both durable and reliable. Enter the 10 gauge welded wire mesh—a product that stands at the forefront of strength and versatility. With decades of industry expertise and extensive hands-on experience, it's clear why this material is becoming the preferred choice for professionals and homeowners alike.

The versatility of 10 gauge welded wire mesh cannot be overstated. Beyond its primary use in agriculture and construction, it has found a home in creative applications such as trellises for horticulture, partitions in industrial settings, and even as a base for sculptural art. Its ability to be cut, shaped, and customized without losing integrity makes it a favorite among architects and designers seeking aesthetically pleasing yet functional solutions. For those considering eco-friendly options, welded wire mesh is recyclable, contributing to sustainable practices. As industries move towards greener solutions, incorporating materials like this demonstrates a commitment to environmental responsibility. Considering the breadth of uses and the inherent qualities, making an informed purchase requires consulting with suppliers known for their expertise. They can provide insights into customizing your mesh for specific needs—whether that involves altering the spacing between wires, selecting an appropriate coating, or ensuring compliance with local regulations. Ultimately, the 10 gauge welded wire mesh is more than just a construction material; it's a pivotal component in projects where safety, durability, and longevity are non-negotiable. By choosing this product, you are not only securing the integrity of your work but also incurring lasting benefits that extend beyond immediate utility. As such, it's an investment that pays dividends in reliability and peace of mind, ensuring your project stands the test of time.

The versatility of 10 gauge welded wire mesh cannot be overstated. Beyond its primary use in agriculture and construction, it has found a home in creative applications such as trellises for horticulture, partitions in industrial settings, and even as a base for sculptural art. Its ability to be cut, shaped, and customized without losing integrity makes it a favorite among architects and designers seeking aesthetically pleasing yet functional solutions. For those considering eco-friendly options, welded wire mesh is recyclable, contributing to sustainable practices. As industries move towards greener solutions, incorporating materials like this demonstrates a commitment to environmental responsibility. Considering the breadth of uses and the inherent qualities, making an informed purchase requires consulting with suppliers known for their expertise. They can provide insights into customizing your mesh for specific needs—whether that involves altering the spacing between wires, selecting an appropriate coating, or ensuring compliance with local regulations. Ultimately, the 10 gauge welded wire mesh is more than just a construction material; it's a pivotal component in projects where safety, durability, and longevity are non-negotiable. By choosing this product, you are not only securing the integrity of your work but also incurring lasting benefits that extend beyond immediate utility. As such, it's an investment that pays dividends in reliability and peace of mind, ensuring your project stands the test of time.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

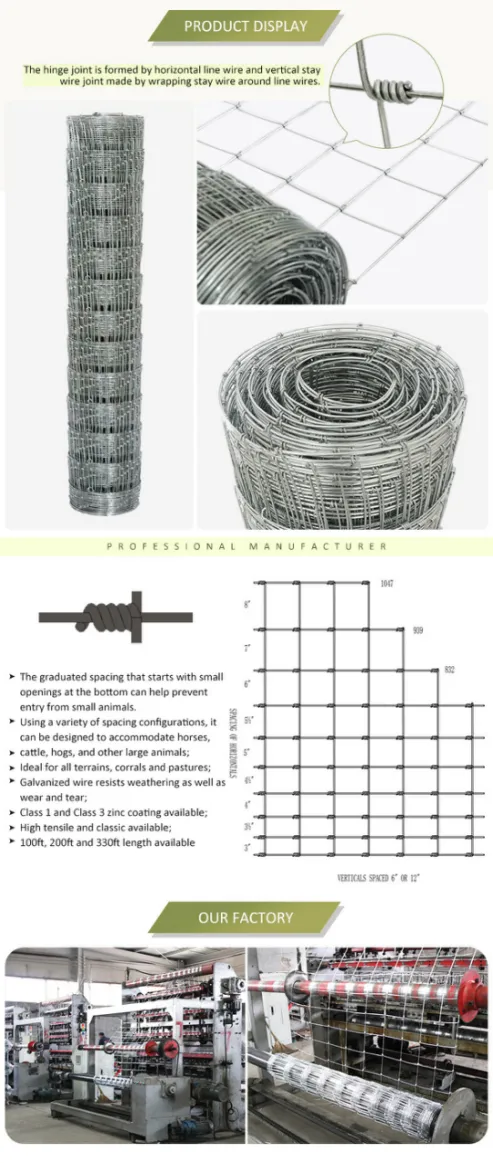

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024