2 月 . 14, 2025 07:33 Back to list

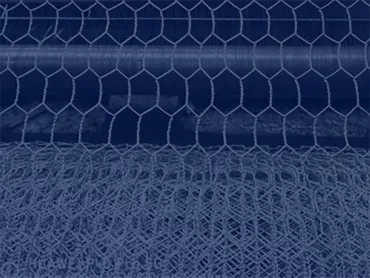

1 4 galvanized wire mesh

Galvanized wire mesh is an essential component in numerous industries, revered for its strength, durability, and versatility. The keyword 1 4 galvanized wire mesh refers to a specific type of this product, distinguished by its particular gauge and design, which guarantees a multitude of applications and solutions across various sectors.

Manufacturers of galvanized wire mesh adhere to global quality standards, including ISO certifications, to assure clients of their commitment to excellence. This authoritative endorsement reflects not only the proficiency of manufacturers but also the superior quality of the product. Regular audits and certifications further solidify the trustworthiness of the mesh, validating its use in projects requiring high safety and quality assurance standards. For DIY enthusiasts and small-scale projects, the 1 4 galvanized wire mesh offers noteworthy flexibility and ease of use. It can be easily manipulated and cut to desired specifications without compromising the integrity of the zinc coating. This adaptability makes it an excellent choice for crafting custom protective screens, garden enclosures, and even creative art installations. Hobbyists appreciate the product's resilience and aesthetic versatility, allowing for projects that are both functional and pleasing to the eye. From an environmental perspective, galvanized wire mesh underscores a commitment to sustainable practices. The zinc coating not only enhances the longevity of the steel but also reduces wastage and the need for frequent replacement, contributing to reduced industrial waste and resource consumption. Furthermore, galvanized products are recyclable, aligning with growing environmental consciousness and the global push for eco-friendly solutions. In conclusion, the application of 1 4 galvanized wire mesh across multiple sectors showcases its indispensable role in modern infrastructure, agriculture, and creative endeavors. Its blend of durability, cost-effectiveness, and environmental friendliness ensures its continued relevance in an ever-evolving market. Whether for industrial heavyweights or individual consumers, this specific type of wire mesh stands as a testament to quality and reliability, fostering trust and collaborative growth across global markets.

Manufacturers of galvanized wire mesh adhere to global quality standards, including ISO certifications, to assure clients of their commitment to excellence. This authoritative endorsement reflects not only the proficiency of manufacturers but also the superior quality of the product. Regular audits and certifications further solidify the trustworthiness of the mesh, validating its use in projects requiring high safety and quality assurance standards. For DIY enthusiasts and small-scale projects, the 1 4 galvanized wire mesh offers noteworthy flexibility and ease of use. It can be easily manipulated and cut to desired specifications without compromising the integrity of the zinc coating. This adaptability makes it an excellent choice for crafting custom protective screens, garden enclosures, and even creative art installations. Hobbyists appreciate the product's resilience and aesthetic versatility, allowing for projects that are both functional and pleasing to the eye. From an environmental perspective, galvanized wire mesh underscores a commitment to sustainable practices. The zinc coating not only enhances the longevity of the steel but also reduces wastage and the need for frequent replacement, contributing to reduced industrial waste and resource consumption. Furthermore, galvanized products are recyclable, aligning with growing environmental consciousness and the global push for eco-friendly solutions. In conclusion, the application of 1 4 galvanized wire mesh across multiple sectors showcases its indispensable role in modern infrastructure, agriculture, and creative endeavors. Its blend of durability, cost-effectiveness, and environmental friendliness ensures its continued relevance in an ever-evolving market. Whether for industrial heavyweights or individual consumers, this specific type of wire mesh stands as a testament to quality and reliability, fostering trust and collaborative growth across global markets.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024