2 月 . 14, 2025 12:12 Back to list

14 gauge galvanized welded wire

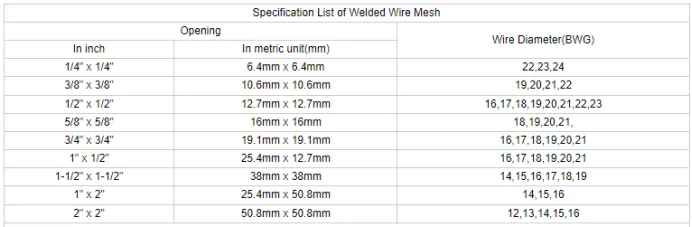

The versatility and durability of 14 gauge galvanized welded wire make it an invaluable asset in various applications. This specific type of welded wire mesh is known for its robustness, corrosion resistance, and versatile utility across industries, cementing its status as a trusted choice among professionals seeking long-lasting solutions. Its gauge signifies a formidable balance between strength and flexibility, providing an ideal solution for both agricultural and commercial needs.

Residential applications also highlight the practicality of 14 gauge galvanized welded wire. Homeowners utilize it for garden protection, creating barriers that keep pests out while allowing plants to flourish undisturbed. It serves as a protective element for patios and recreational areas, affording peace of mind without obstructing views or detracting from the environment's aesthetic appeal. Its installation is straightforward, accommodating DIY projects for those inclined to undertake home improvement tasks themselves. From an expertise standpoint, understanding the characteristics of the gauge is pivotal when selecting welded wire mesh for specific projects. The 14 gauge thickness offers a perfect balance; it is thin enough for easy handling and shaping yet robust enough to withstand forceful impact. This gauge is thicker than lighter alternatives, providing enhanced protection while retaining a degree of flexibility necessary for various installations. Professionals often recommend it for settings where both durability and adaptability are essential. In terms of trustworthiness and authoritativeness, manufacturers of 14 gauge galvanized welded wire emphasize rigorous quality control processes to ensure each batch meets industry standards. These processes include stringent testing for tensile strength, coating uniformity, and resistance to deformities, supporting the reliability of the product. Professionals advocating for its use often cite this material's consistent quality and performance metrics, reinforcing consumer confidence in its application across diverse settings. Overall, selecting 14 gauge galvanized welded wire translates into a strategic investment combining expertise, quality, and trust. It offers a harmonious blend of strength, adaptability, and longevity suited to professionals across industries who require dependable fencing and structural solutions. In a competitive market, choosing this material not only aligns with practical demands but also aligns with environmentally conscious practices due to its long lifespan and reduced need for frequent replacement, ultimately proving its value as more than just a structural component, but as a cornerstone of efficient and effective project execution.

Residential applications also highlight the practicality of 14 gauge galvanized welded wire. Homeowners utilize it for garden protection, creating barriers that keep pests out while allowing plants to flourish undisturbed. It serves as a protective element for patios and recreational areas, affording peace of mind without obstructing views or detracting from the environment's aesthetic appeal. Its installation is straightforward, accommodating DIY projects for those inclined to undertake home improvement tasks themselves. From an expertise standpoint, understanding the characteristics of the gauge is pivotal when selecting welded wire mesh for specific projects. The 14 gauge thickness offers a perfect balance; it is thin enough for easy handling and shaping yet robust enough to withstand forceful impact. This gauge is thicker than lighter alternatives, providing enhanced protection while retaining a degree of flexibility necessary for various installations. Professionals often recommend it for settings where both durability and adaptability are essential. In terms of trustworthiness and authoritativeness, manufacturers of 14 gauge galvanized welded wire emphasize rigorous quality control processes to ensure each batch meets industry standards. These processes include stringent testing for tensile strength, coating uniformity, and resistance to deformities, supporting the reliability of the product. Professionals advocating for its use often cite this material's consistent quality and performance metrics, reinforcing consumer confidence in its application across diverse settings. Overall, selecting 14 gauge galvanized welded wire translates into a strategic investment combining expertise, quality, and trust. It offers a harmonious blend of strength, adaptability, and longevity suited to professionals across industries who require dependable fencing and structural solutions. In a competitive market, choosing this material not only aligns with practical demands but also aligns with environmentally conscious practices due to its long lifespan and reduced need for frequent replacement, ultimately proving its value as more than just a structural component, but as a cornerstone of efficient and effective project execution.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024