3 月 . 05, 2025 01:17 Back to list

16d common nails for nail gun

When it comes to construction efficiency, the integration of technology and traditional tools is indispensable. Using 16d common nails for a nail gun exemplifies such innovation, streamlining your construction processes with precision and consistency. This fusion of tools advances the way carpentry and framing projects are efficiently executed, resulting in robust and reliable structures.

The reliance on these materials and tools goes hand in hand with building regulations that govern structural safety. Familiarity with local building codes and standards is crucial, as non-compliance can result in structural faults and legal complications. Engaging with an authoritative source on construction guidelines can provide updated insights, ensuring your work aligns with current safety and ecological standards. On the trustworthiness scale, product reviews and ratings from authoritative construction trade sites can provide additional reassurance when selecting the best 16d common nails for your project. Customer testimonials and professional evaluations often shed light on real-world performance and reliability, guiding informed decisions in tool and material procurement. The seamless integration of 16d common nails tailored for nail guns symbolizes a transition towards more efficient and sophisticated construction methodologies. By embracing this combination, professionals are equipped for an elevated experience in construction projects, marked by enhanced productivity, quality assurance, and safety. These attributes not only benefit the craftsman but also end-users, providing them with structures that stand the test of time and weather. In summary, the adoption of 16d common nails for nail guns represents a confluence of traditional craftsmanship and modern technology. The drive towards efficiency and excellence in construction is not only about using advanced tools but also about leveraging expertise and authoritative guidance to make smarter, more sustainable building choices. By emphasizing these elements, the result is a more trusted, durable, and expertly crafted world.

The reliance on these materials and tools goes hand in hand with building regulations that govern structural safety. Familiarity with local building codes and standards is crucial, as non-compliance can result in structural faults and legal complications. Engaging with an authoritative source on construction guidelines can provide updated insights, ensuring your work aligns with current safety and ecological standards. On the trustworthiness scale, product reviews and ratings from authoritative construction trade sites can provide additional reassurance when selecting the best 16d common nails for your project. Customer testimonials and professional evaluations often shed light on real-world performance and reliability, guiding informed decisions in tool and material procurement. The seamless integration of 16d common nails tailored for nail guns symbolizes a transition towards more efficient and sophisticated construction methodologies. By embracing this combination, professionals are equipped for an elevated experience in construction projects, marked by enhanced productivity, quality assurance, and safety. These attributes not only benefit the craftsman but also end-users, providing them with structures that stand the test of time and weather. In summary, the adoption of 16d common nails for nail guns represents a confluence of traditional craftsmanship and modern technology. The drive towards efficiency and excellence in construction is not only about using advanced tools but also about leveraging expertise and authoritative guidance to make smarter, more sustainable building choices. By emphasizing these elements, the result is a more trusted, durable, and expertly crafted world.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

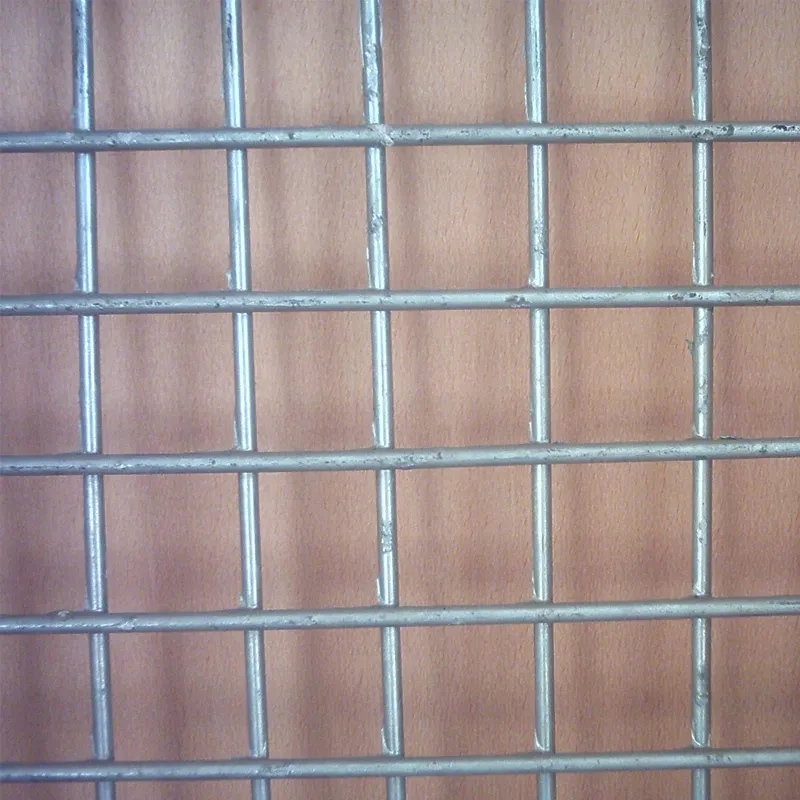

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024