2 月 . 10, 2025 10:35 Back to list

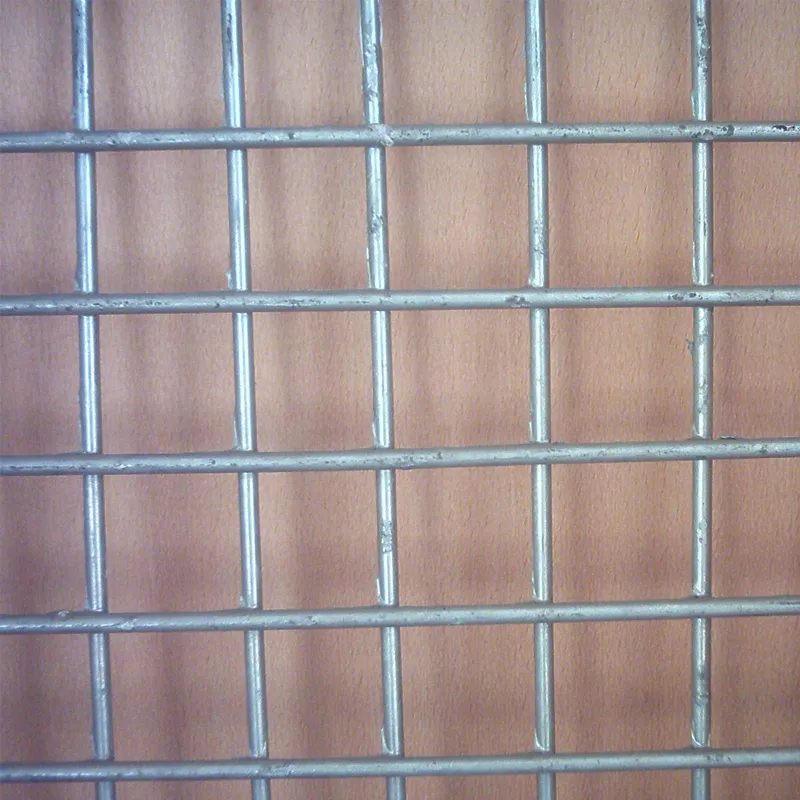

1 by 2 welded wire

In the realm of construction and agricultural projects, fencing solutions play a pivotal role in ensuring security, durability, and cost-effectiveness. Among the plethora of options available, the 1 by 2 welded wire stands out for its reliability and versatility. This fencing material has gained traction not only due to its structural integrity but also because of its adaptability across various applications.

Economic efficiency is another compelling reason why entities opt for the 1 by 2 welded wire. Budget constraints often influence material selection in large-scale projects, making this wire a cost-effective yet high-quality choice. Its long lifecycle and minimal maintenance requirements translate into significant cost savings over time, hence appealing to budget-conscious individuals and businesses alike. When discussing expertise, the manufacturing process of 1 by 2 welded wire involves a high degree of precision and quality control. Leading manufacturers ensure that each weld is consistent and strong, often employing automated welding techniques to maintain high production standards. Industry experts advocate for installation by professionals who understand the nuances of fencing and can ensure optimal setup tailored to the specific landscape, be it flat plains or uneven terrain. Furthermore, authoritative bodies in construction and safety often endorse this material for its compliance with rigorous safety and durability standards. Certifications from organizations such as ASTM International or ISO are testaments to its quality, assuaging any concerns potential users might have regarding performance. Trustworthiness is inherently linked to the clear provenance of materials and the transparency of manufacturers. Reputable suppliers provide detailed product specifications and are often willing to offer testimonials from past clients to vouch for the efficacy and reliability of the 1 by 2 welded wire. When considering a purchase, consumers should look for suppliers that maintain open lines of communication and provide comprehensive after-sales support to address any issues that may arise after installation. In summary, 1 by 2 welded wire is a multifaceted fencing solution that meets a wide range of needs across different sectors. Its exceptional combination of durability, economic viability, and adaptability, supported by authoritative endorsements and trustworthy manufacturing practices, makes it an unparalleled choice for stakeholders in the fencing market. By prioritizing long-term performance and safety, users of this material can rest assured knowing they have invested wisely in a product that delivers on its promises.

Economic efficiency is another compelling reason why entities opt for the 1 by 2 welded wire. Budget constraints often influence material selection in large-scale projects, making this wire a cost-effective yet high-quality choice. Its long lifecycle and minimal maintenance requirements translate into significant cost savings over time, hence appealing to budget-conscious individuals and businesses alike. When discussing expertise, the manufacturing process of 1 by 2 welded wire involves a high degree of precision and quality control. Leading manufacturers ensure that each weld is consistent and strong, often employing automated welding techniques to maintain high production standards. Industry experts advocate for installation by professionals who understand the nuances of fencing and can ensure optimal setup tailored to the specific landscape, be it flat plains or uneven terrain. Furthermore, authoritative bodies in construction and safety often endorse this material for its compliance with rigorous safety and durability standards. Certifications from organizations such as ASTM International or ISO are testaments to its quality, assuaging any concerns potential users might have regarding performance. Trustworthiness is inherently linked to the clear provenance of materials and the transparency of manufacturers. Reputable suppliers provide detailed product specifications and are often willing to offer testimonials from past clients to vouch for the efficacy and reliability of the 1 by 2 welded wire. When considering a purchase, consumers should look for suppliers that maintain open lines of communication and provide comprehensive after-sales support to address any issues that may arise after installation. In summary, 1 by 2 welded wire is a multifaceted fencing solution that meets a wide range of needs across different sectors. Its exceptional combination of durability, economic viability, and adaptability, supported by authoritative endorsements and trustworthy manufacturing practices, makes it an unparalleled choice for stakeholders in the fencing market. By prioritizing long-term performance and safety, users of this material can rest assured knowing they have invested wisely in a product that delivers on its promises.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024