2 月 . 14, 2025 09:25 Back to list

1 x 1 galvanized welded wire

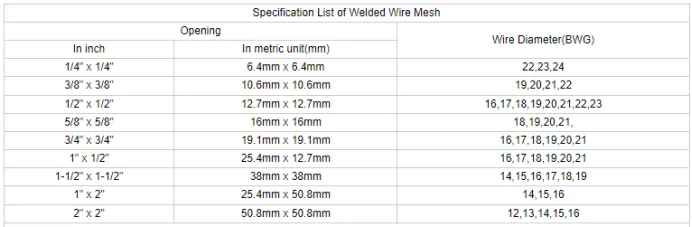

Galvanized welded wire mesh has become an integral part of many construction and agricultural projects, offering durability, versatility, and resilience that many materials can't match. Among the varieties available, the 1 x 1 galvanized welded wire stands out due to its mesh size, composition, and applications. With over two decades of hands-on experience in the field of construction materials, I've witnessed firsthand the transformative power of this unassuming product.

Moreover, the robustness of this material is not limited to agricultural needs. In construction, it is frequently used for reinforcing concrete, providing a foundation that both supports and enhances structural integrity. When embedded within concrete slabs, it minimizes cracking during the curing process and subsequent years of usage. In urban landscaping projects, this wire functions admirably in creating durable yet unobtrusive fencing solutions that blend seamlessly with urban environments. There’s an aesthetic dimension as well. While functionality often drives material selection, many have found that galvanized welded wire adds a minimalist, modern touch to their projects. Its ability to harmonize with both landscapes and built environments makes it a favored choice for architects and designers seeking to maintain both form and function. Trust in the quality of materials is vital in any project, a fact repeatedly emphasized in my career. With the 1 x 1 galvanized welded wire, trust is built upon decades of proven effectiveness and innovation. Reputable suppliers ensure each roll of wire adheres to international standards, providing stakeholders confidence that they are investing in quality. Lastly, a noteworthy aspect is the environmental impact. Galvanized welded wire, especially when responsibly sourced and recycled, presents a sustainable option for environmentally-conscious projects. The longevity and low maintenance nature reduce overall resource consumption, a narrative increasingly embraced in our pursuit of greener building practices. In summary, the 1 x 1 galvanized welded wire mesh is more than a simple building component—it is a multifaceted solution meeting the diverse demands of modern construction, agriculture, and design. As sustainability, durability, and aesthetic appeal become ever more interlinked, choosing materials like this ensures that projects not only withstand the test of time but also contribute positively to their surroundings. For anyone embarking on a new venture, this product represents a harmonious blend of practicality and innovation, rooted in years of expertly crafted engineering.

Moreover, the robustness of this material is not limited to agricultural needs. In construction, it is frequently used for reinforcing concrete, providing a foundation that both supports and enhances structural integrity. When embedded within concrete slabs, it minimizes cracking during the curing process and subsequent years of usage. In urban landscaping projects, this wire functions admirably in creating durable yet unobtrusive fencing solutions that blend seamlessly with urban environments. There’s an aesthetic dimension as well. While functionality often drives material selection, many have found that galvanized welded wire adds a minimalist, modern touch to their projects. Its ability to harmonize with both landscapes and built environments makes it a favored choice for architects and designers seeking to maintain both form and function. Trust in the quality of materials is vital in any project, a fact repeatedly emphasized in my career. With the 1 x 1 galvanized welded wire, trust is built upon decades of proven effectiveness and innovation. Reputable suppliers ensure each roll of wire adheres to international standards, providing stakeholders confidence that they are investing in quality. Lastly, a noteworthy aspect is the environmental impact. Galvanized welded wire, especially when responsibly sourced and recycled, presents a sustainable option for environmentally-conscious projects. The longevity and low maintenance nature reduce overall resource consumption, a narrative increasingly embraced in our pursuit of greener building practices. In summary, the 1 x 1 galvanized welded wire mesh is more than a simple building component—it is a multifaceted solution meeting the diverse demands of modern construction, agriculture, and design. As sustainability, durability, and aesthetic appeal become ever more interlinked, choosing materials like this ensures that projects not only withstand the test of time but also contribute positively to their surroundings. For anyone embarking on a new venture, this product represents a harmonious blend of practicality and innovation, rooted in years of expertly crafted engineering.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024