2 月 . 10, 2025 22:54 Back to list

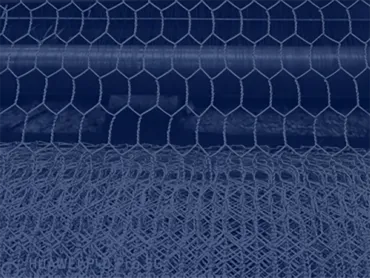

Galvanized Welded Wire Mesh

For those interested in enhancing security, ensuring safety, or facilitating construction projects, 2x2 welded wire mesh has become an indispensable component in various industries. This fundamental product combines precision engineering with durability, making it a staple for professionals across the globe. Here's a deep dive into the world of 2x2 welded wire mesh, focusing on its applications, advantages, and considerations essential for informed decision-making.

The expertise in choosing the correct wire diameter is another pivotal consideration. The thicker the wire, the more durable and supportive it becomes. In settings where high tensile strength is a necessity, such as in road works or heavy-duty animal enclosures, opting for a thicker gauge is advisable. The balance between diameter and weight is crucial to maintain efficiency and effectiveness across applications. Authoritativeness in installation procedures ensures that the 2x2 welded wire mesh performs optimally. Correct installation is crucial; experts often guide the installation process, ensuring that the mesh is tightly stretched and secured. Whether it's embedding within concrete or using it as standalone fencing, professional installation optimally preserves structural integrity and functional longevity. Trustworthiness in suppliers cannot be overlooked. Established manufacturers provide certifications and warranties, signifying compliance with industry standards and guaranteeing product quality. Engaging with reputable suppliers ensures access to high-quality materials, comprehensive post-purchase support, and a trusted partnership that extends beyond mere transactions. Furthermore, sustainable practices in the production and disposal of 2x2 welded wire mesh align with the growing demand for environmentally conscious products. A commitment to ethical sourcing and production processes adds another layer of trustworthiness for consumers seeking long-term ecological impacts. Many manufacturers are now focused on recycling initiatives or offer buy-back programs for used meshes, supporting a circular economy. In conclusion, the 2x2 welded wire mesh is more than just a simple grid of wires. Its multifaceted applications, from reinforcing concrete to securing perimeters and supporting agricultural activities, render it a critical asset across industries. The product's reliability hinges on detailed knowledge of material quality, proficiency in installation, and trustworthy sourcing, balanced with a growing focus on environmental responsibility. By prioritizing these considerations, professionals can harness the full potential of welded wire mesh, supporting robust, secure, and sustainable developments.

The expertise in choosing the correct wire diameter is another pivotal consideration. The thicker the wire, the more durable and supportive it becomes. In settings where high tensile strength is a necessity, such as in road works or heavy-duty animal enclosures, opting for a thicker gauge is advisable. The balance between diameter and weight is crucial to maintain efficiency and effectiveness across applications. Authoritativeness in installation procedures ensures that the 2x2 welded wire mesh performs optimally. Correct installation is crucial; experts often guide the installation process, ensuring that the mesh is tightly stretched and secured. Whether it's embedding within concrete or using it as standalone fencing, professional installation optimally preserves structural integrity and functional longevity. Trustworthiness in suppliers cannot be overlooked. Established manufacturers provide certifications and warranties, signifying compliance with industry standards and guaranteeing product quality. Engaging with reputable suppliers ensures access to high-quality materials, comprehensive post-purchase support, and a trusted partnership that extends beyond mere transactions. Furthermore, sustainable practices in the production and disposal of 2x2 welded wire mesh align with the growing demand for environmentally conscious products. A commitment to ethical sourcing and production processes adds another layer of trustworthiness for consumers seeking long-term ecological impacts. Many manufacturers are now focused on recycling initiatives or offer buy-back programs for used meshes, supporting a circular economy. In conclusion, the 2x2 welded wire mesh is more than just a simple grid of wires. Its multifaceted applications, from reinforcing concrete to securing perimeters and supporting agricultural activities, render it a critical asset across industries. The product's reliability hinges on detailed knowledge of material quality, proficiency in installation, and trustworthy sourcing, balanced with a growing focus on environmental responsibility. By prioritizing these considerations, professionals can harness the full potential of welded wire mesh, supporting robust, secure, and sustainable developments.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024