2 月 . 11, 2025 17:14 Back to list

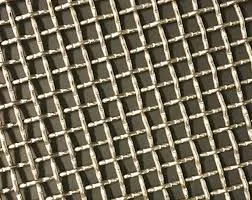

50mm weld mesh

50mm weld mesh has emerged as one of the most versatile and trusted solutions in industries requiring robust and flexible materials. With its intrinsic properties, this weld mesh is widely applicable in construction, agriculture, and a multitude of industrial uses, ensuring safety, structural integrity, and cost-effectiveness.

Durability is a definitive feature attributed to the 50mm weld mesh, which directly correlates to its expertise within industry circles. The material's resilience against wear and tear results from a galvanization process, when required, that adds a layer of zinc to protect against rust and corrosion, especially when deployed in outdoor environments. Consequently, this feature is widely praised in sectors where corrosion resistance is critical. Authoritativeness in the use of this product can be seen through various certifications and compliance standards governing weld mesh manufacturing. Manufacturers often adhere to international quality standards like ISO 9001, which reinforces the product’s reliability and trustworthiness. The assurance of meeting these standards builds confidence among users, ranging from small business operations to large industrial firms. Moreover, customer testimonials frequently reflect the product's trustworthiness. Users often emphasize their satisfaction with the product's longevity and effectiveness, which aligns with the experiences shared by experts who advocate for its use in rigorous applications. Such endorsements not only bolster consumer confidence but also cement the product's reputation in diverse markets. To sum up, the 50mm weld mesh embodies a comprehensive blend of strength, flexibility, and sustainability. Its applications transcend across various sectors, backed by robust manufacturing processes and adherence to quality standards. For businesses and individuals seeking a reliable, versatile, and efficient solution for their projects, this weld mesh offers unmatched authority and stands as a testament to modern engineering prowess, ensuring long-term success in every application.

Durability is a definitive feature attributed to the 50mm weld mesh, which directly correlates to its expertise within industry circles. The material's resilience against wear and tear results from a galvanization process, when required, that adds a layer of zinc to protect against rust and corrosion, especially when deployed in outdoor environments. Consequently, this feature is widely praised in sectors where corrosion resistance is critical. Authoritativeness in the use of this product can be seen through various certifications and compliance standards governing weld mesh manufacturing. Manufacturers often adhere to international quality standards like ISO 9001, which reinforces the product’s reliability and trustworthiness. The assurance of meeting these standards builds confidence among users, ranging from small business operations to large industrial firms. Moreover, customer testimonials frequently reflect the product's trustworthiness. Users often emphasize their satisfaction with the product's longevity and effectiveness, which aligns with the experiences shared by experts who advocate for its use in rigorous applications. Such endorsements not only bolster consumer confidence but also cement the product's reputation in diverse markets. To sum up, the 50mm weld mesh embodies a comprehensive blend of strength, flexibility, and sustainability. Its applications transcend across various sectors, backed by robust manufacturing processes and adherence to quality standards. For businesses and individuals seeking a reliable, versatile, and efficient solution for their projects, this weld mesh offers unmatched authority and stands as a testament to modern engineering prowess, ensuring long-term success in every application.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024