2 月 . 12, 2025 19:19 Back to list

building a welded wire fence

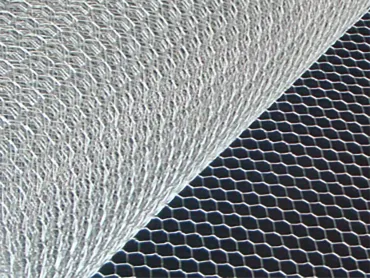

Building a welded wire fence offers a practical and versatile solution for various fencing needs, from protecting your garden to securing pets and livestock. Welded wire fencing, known for its durability and resilience, stands out due to its strength and adaptability to different terrains. As someone with extensive experience in fence installation, I will guide you through the critical steps and considerations needed to construct a robust welded wire fence.

In areas prone to high winds or animal pressure, consider reinforcing your fence with additional support wires or even a double-layer fence arrangement. This enhances durability, ensures the fence remains intact under stress, and minimizes maintenance needs. Throughout the process, safety should remain a priority. Use gloves to protect against sharp wire edges and wear safety goggles during cutting and stretching to shield your eyes from stray wire ends. The installation process demands meticulous attention to detail, ensuring every component is correctly installed and secured. Once completed, a welded wire fence not only defines boundaries but also adds value to your property. It serves multiple purposes—keeping unwanted wildlife out of gardens, securing pets and livestock, and offering a structure for climbing plants. Moreover, its transparent nature means it won’t obstruct views, maintaining the aesthetic appeal of the surrounding landscape. To ensure long-term reliability, undertake regular inspections. Check for signs of wear, rust, or damage, especially after severe weather events. Prompt repairs, such as replacing damaged sections or re-tightening loose wires, are essential to maintain the fence’s integrity and functionality. In conclusion, constructing a welded wire fence involves careful planning, the right materials, and skilled execution. Drawing from industry expertise can transform what might seem like a daunting task into a fulfilling project. As a testament to your dedication and craftsmanship, a well-installed fence not only meets practical needs but also enhances the beauty and security of your property. Embrace the process, and let your efforts speak of your commitment to quality and excellence.

In areas prone to high winds or animal pressure, consider reinforcing your fence with additional support wires or even a double-layer fence arrangement. This enhances durability, ensures the fence remains intact under stress, and minimizes maintenance needs. Throughout the process, safety should remain a priority. Use gloves to protect against sharp wire edges and wear safety goggles during cutting and stretching to shield your eyes from stray wire ends. The installation process demands meticulous attention to detail, ensuring every component is correctly installed and secured. Once completed, a welded wire fence not only defines boundaries but also adds value to your property. It serves multiple purposes—keeping unwanted wildlife out of gardens, securing pets and livestock, and offering a structure for climbing plants. Moreover, its transparent nature means it won’t obstruct views, maintaining the aesthetic appeal of the surrounding landscape. To ensure long-term reliability, undertake regular inspections. Check for signs of wear, rust, or damage, especially after severe weather events. Prompt repairs, such as replacing damaged sections or re-tightening loose wires, are essential to maintain the fence’s integrity and functionality. In conclusion, constructing a welded wire fence involves careful planning, the right materials, and skilled execution. Drawing from industry expertise can transform what might seem like a daunting task into a fulfilling project. As a testament to your dedication and craftsmanship, a well-installed fence not only meets practical needs but also enhances the beauty and security of your property. Embrace the process, and let your efforts speak of your commitment to quality and excellence.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024