1 月 . 16, 2025 02:08 Back to list

cage wire panels

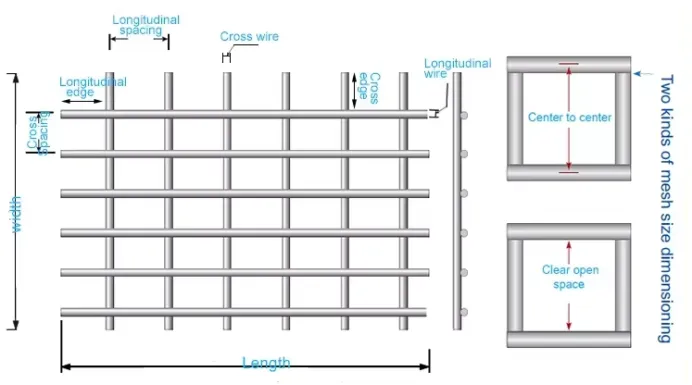

Navigating the intricacies of cage wire panels can be complex without the right guidance. These panels, essential for a multitude of applications, from residential to industrial uses, are heralded for their versatility and robustness. Ideal for securing spaces such as animal enclosures, garden fencing, or even intricate architectural structures, cage wire panels serve many critical roles across sectors.

For industry professionals and DIY enthusiasts alike, installing cage wire panels requires understanding proper securing techniques. Using appropriate braces, ties, and fasteners ensures the panels remain both taut and secure over time, a critical factor for long-term reliability. Guidance from experienced installers not only optimizes safety but also enhances aesthetic appeal, and their professional input can make a significant difference in execution quality. Manufacturer credibility hinges on a legacy of quality and innovation. Trust in a brand often stems from years of consistent product excellence and customer satisfaction. Checking for certifications and endorsements from recognized industry bodies can provide assurance in their authority and commitment to industry standards. Customer reviews and case studies can also offer invaluable insights into a product’s real-world performance and usability. Building trust with potential buyers involves transparency in communication—clearly outlining product specifications, providing detailed installation instructions, and offering robust customer service support post-purchase. Companies that thrive are those who build relationships based on trust, reliability, and mutual respect, encouraging repeat patronage through value-added services and technical support. Ultimately, cage wire panels offer a combination of strength, customizability, and practicality, catering to diverse needs with precision and reliability. Their continued evolution is driven by efforts to enhance performance, sustainability, and user satisfaction, aligning with industry trends and consumer preferences. Exploring the comprehensive benefits of these panels can empower informed decision-making, ensuring that their integration into any space is both seamless and advantageous.

For industry professionals and DIY enthusiasts alike, installing cage wire panels requires understanding proper securing techniques. Using appropriate braces, ties, and fasteners ensures the panels remain both taut and secure over time, a critical factor for long-term reliability. Guidance from experienced installers not only optimizes safety but also enhances aesthetic appeal, and their professional input can make a significant difference in execution quality. Manufacturer credibility hinges on a legacy of quality and innovation. Trust in a brand often stems from years of consistent product excellence and customer satisfaction. Checking for certifications and endorsements from recognized industry bodies can provide assurance in their authority and commitment to industry standards. Customer reviews and case studies can also offer invaluable insights into a product’s real-world performance and usability. Building trust with potential buyers involves transparency in communication—clearly outlining product specifications, providing detailed installation instructions, and offering robust customer service support post-purchase. Companies that thrive are those who build relationships based on trust, reliability, and mutual respect, encouraging repeat patronage through value-added services and technical support. Ultimately, cage wire panels offer a combination of strength, customizability, and practicality, catering to diverse needs with precision and reliability. Their continued evolution is driven by efforts to enhance performance, sustainability, and user satisfaction, aligning with industry trends and consumer preferences. Exploring the comprehensive benefits of these panels can empower informed decision-making, ensuring that their integration into any space is both seamless and advantageous.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024