1 月 . 15, 2025 09:35 Back to list

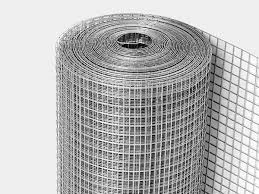

chicken mesh

Chicken mesh, also known as poultry netting or hexagonal wire netting, has been an integral part of agricultural and construction industries for decades. Despite its humble appearance, this versatile product serves as a testament to innovation and utility. Its application spans from safeguarding livestock to being pivotal in construction projects, showcasing an extensive experience across various domains.

Trustworthiness is a cornerstone of chicken mesh’s reputation. For generations, landscapers, builders, and farmers alike have relied on its dependable structure. Quality assurance is key; therefore, it's important that consumers source their chicken mesh from reputable suppliers who adhere to stringent manufacturing standards. Proper quality checks ensure that the mesh’s tensile strength and weather resistance meet the rigorous demands of both DIY enthusiasts and industry professionals. Recent innovations have further cemented chicken mesh's status as an indispensable tool. Eco-friendly coatings and advanced galvanization techniques have been developed, ensuring minimal environmental impact without compromising on performance. This forward-thinking approach aligns with global trends towards sustainable practices, allowing chicken mesh to maintain its legacy as a responsible and effective solution. For those embarking on home improvement projects or managing agricultural operations, understanding the specialized use cases and qualities of chicken mesh can enhance outcomes significantly. Whether constructing a secure chicken coop or integrating it within a structural element, the potential of this material is only limited by one’s imagination and expertise in its application. Ultimately, chicken mesh embodies a blend of historical significance, technical proficiency, and innovative evolution. Its enduring presence is a testament not only to its functional benefits but also to the trust it has earned across various industries. Those seeking a reliable, adaptable, and environmentally conscious material will find that chicken mesh continues to deliver exceptional value and performance, confirming its status as a staple in both agricultural and construction settings.

Trustworthiness is a cornerstone of chicken mesh’s reputation. For generations, landscapers, builders, and farmers alike have relied on its dependable structure. Quality assurance is key; therefore, it's important that consumers source their chicken mesh from reputable suppliers who adhere to stringent manufacturing standards. Proper quality checks ensure that the mesh’s tensile strength and weather resistance meet the rigorous demands of both DIY enthusiasts and industry professionals. Recent innovations have further cemented chicken mesh's status as an indispensable tool. Eco-friendly coatings and advanced galvanization techniques have been developed, ensuring minimal environmental impact without compromising on performance. This forward-thinking approach aligns with global trends towards sustainable practices, allowing chicken mesh to maintain its legacy as a responsible and effective solution. For those embarking on home improvement projects or managing agricultural operations, understanding the specialized use cases and qualities of chicken mesh can enhance outcomes significantly. Whether constructing a secure chicken coop or integrating it within a structural element, the potential of this material is only limited by one’s imagination and expertise in its application. Ultimately, chicken mesh embodies a blend of historical significance, technical proficiency, and innovative evolution. Its enduring presence is a testament not only to its functional benefits but also to the trust it has earned across various industries. Those seeking a reliable, adaptable, and environmentally conscious material will find that chicken mesh continues to deliver exceptional value and performance, confirming its status as a staple in both agricultural and construction settings.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024