1 月 . 15, 2025 09:12 Back to list

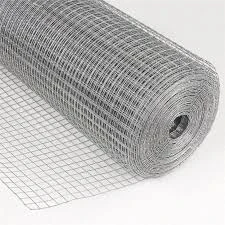

concrete wire mesh for sale

Navigating the complex landscape of construction materials, one component stands out for its critical role in enhancing structural integrity and longevity concrete wire mesh. This product, often unnoticed, provides the essential support framework that upholds the robustness of concrete structures, making it a staple in modern construction projects.

Incorporating a concrete wire mesh into construction projects not only bolsters structural integrity but also translates into long-term cost efficiency. By minimizing potential damage and maintenance needs, contractors and clients alike witness reduced lifecycle costs. This pragmatic approach underlines the expertise required in choosing and implementing reinforcing mesh effectively. Educating oneself about the versatile applications and benefits of concrete wire mesh is an investment in both current and future projects. Resources such as industry publications, certifications, and expert consultations can provide invaluable insights. Such education not only empowers professionals but establishes authoritative knowledge that supports informed decision-making. Finally, while sourcing wire mesh, consider suppliers offering bulk sales and customized options to suit diverse construction needs. Engaging with a supplier who prioritizes quality and sustainable production practices further enhances credibility and aligns with industry-wide shifts towards environmental responsibility. The world of construction is ever-evolving, yet the essential role of concrete wire mesh remains constant. By prioritizing expertise, authority, and trust in every purchase decision, industry professionals can ensure that their projects are built on a foundation of reliability and resilience.

Incorporating a concrete wire mesh into construction projects not only bolsters structural integrity but also translates into long-term cost efficiency. By minimizing potential damage and maintenance needs, contractors and clients alike witness reduced lifecycle costs. This pragmatic approach underlines the expertise required in choosing and implementing reinforcing mesh effectively. Educating oneself about the versatile applications and benefits of concrete wire mesh is an investment in both current and future projects. Resources such as industry publications, certifications, and expert consultations can provide invaluable insights. Such education not only empowers professionals but establishes authoritative knowledge that supports informed decision-making. Finally, while sourcing wire mesh, consider suppliers offering bulk sales and customized options to suit diverse construction needs. Engaging with a supplier who prioritizes quality and sustainable production practices further enhances credibility and aligns with industry-wide shifts towards environmental responsibility. The world of construction is ever-evolving, yet the essential role of concrete wire mesh remains constant. By prioritizing expertise, authority, and trust in every purchase decision, industry professionals can ensure that their projects are built on a foundation of reliability and resilience.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024