11 月 . 01, 2024 13:12 Back to list

Essential Guide to Choosing the Right Construction Nails for Your Projects

The Essential Guide to Construction Nails

Construction nails are a fundamental component in building and structural projects. They are often overlooked in favor of larger tools and equipment, yet they provide the crucial fastening that holds projects together. Understanding the types, uses, and specific applications of construction nails can significantly enhance both the efficiency and safety of any construction endeavor.

Types of Construction Nails

There is a diverse range of nails designed for various applications in construction

1. Common Nails These are perhaps the most widely recognized type of construction nail. They are made from steel and are typically used in framing, flooring, and sheathing. Common nails have a thick shaft and are excellent for heavy-duty construction.

2. Box Nails Slightly thinner than common nails, box nails are designed for general construction purposes where less holding power is sufficient. They are ideal for nailing thin wood, such as in box constructions.

3. Finishing Nails These nails have a smaller head and are used in situations where a neat finish is desired. They are typically employed in woodworking projects and cabinetry, as they can be driven below the surface of the wood and easily concealed.

4. Roofing Nails Equipped with a larger head, roofing nails are specifically designed for securing roofing materials like shingles. Their larger heads prevent the shingles from being pulled through the nail, ensuring durability and water resistance.

construction nails

5. Concrete Nails Made from hardened steel, concrete nails are designed to fasten wood to concrete or masonry. They are tough and specifically engineered to endure the impact of being driven into harder surfaces.

Usage and Application

The choice of nail can significantly impact the strength and durability of a construction project. For example, when framing a house, common nails are preferred due to their thickness and holding power. Conversely, during the finishing stages, finishing nails would be used to achieve a clean look without visible fasteners.

The length of the nail also plays a critical role in securing materials effectively. A general rule of thumb is that the nail should be at least twice the thickness of the material being fastened. This ensures a firm hold and minimizes the risk of materials splitting.

Proper technique in driving nails is equally important. Using a hammer or nail gun, the nail should be driven straight to avoid bending or breaking, which could compromise the integrity of the structure. Additionally, taking care to avoid overdriving the nail will prevent damage to the material being fastened.

Considerations for Safety and Durability

Safety should always be a priority on construction sites. When working with nails, it’s essential to wear appropriate personal protective equipment, such as safety glasses, to guard against accidental injury from flying debris. Furthermore, using galvanized or stainless-steel nails in outdoor construction can prevent corrosion, extending the life of the structure and its components.

In conclusion, while construction nails may seem like a small detail in the grand scheme of a building project, they play an integral role in the overall durability and stability of the structure. Understanding the different types, their specific applications, and the importance of correct usage can greatly contribute to the success of any construction endeavor. As technology advances, new types of nails and fastening methods continue to evolve, ensuring that this small but mighty construction component remains relevant in the industry.

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

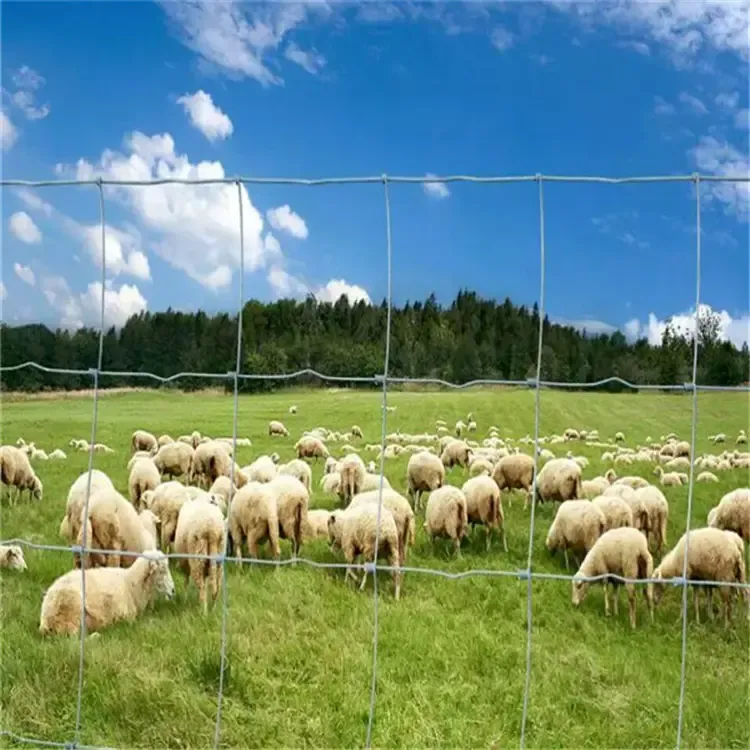

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024