9 月 . 25, 2024 07:21 Back to list

Cut Wire Manufacturing Solutions for Efficient Industrial Applications and Custom Fabrication Services

The Evolution and Impact of Cut Wire Factories

In the world of manufacturing, cut wire factories play a crucial role in producing various wire products that cater to diverse industries. Cut wire refers to wire that has been precisely measured and cut to specified lengths, which can be used in numerous applications, ranging from construction and agriculture to electronics and jewelry making.

Historical Background

The origins of wire production can be traced back to ancient civilizations, where metals were shaped into wires for tools, jewelry, and decorative items. However, the industrial revolution marked a significant turning point in wire manufacturing with the advent of machines that enabled mass production. Cut wire factories emerged as specialized entities to meet the growing demand for uniform wire lengths, thus streamlining production processes across multiple sectors.

Manufacturing Process

The standard process in a cut wire factory involves several stages. First, raw wire coils are sourced from suppliers, typically made of materials like steel, copper, or aluminum. These wires then undergo a rigorous quality inspection to ensure they meet industry standards. Once verified, the wire is fed into cutting machines where it is sliced into predetermined lengths. This can be based on customer specifications or industry norms.

After cutting, the wires may undergo additional treatments such as surface coating, polishing, or bending, depending on the end-use requirements. Quality control continues throughout this process, ensuring that the cut wires are free from defects and meet dimensional tolerances.

Applications of Cut Wire Products

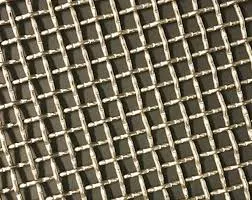

cut wire factory

Cut wire products have diverse applications. In construction, reinforced concrete often uses cut steel wires for strength and support. In the gardening and agricultural sectors, cut wire is employed for trellises, pest control, and fencing. In the electronics industry, precision-cut wires connect components in circuits. Moreover, jewelers utilize cut wire for intricate designs in necklaces, bracelets, and other ornaments.

Benefits of Cut Wire Factories

One of the primary advantages of cut wire factories is their ability to produce customized solutions to meet specific client needs. This flexibility allows for rapid prototyping and ensures that manufacturers can source exactly what they require without excess waste. Additionally, cut wire factories often implement sustainability practices, such as recycling scrap metal, reducing the environmental footprint of their manufacturing processes.

Challenges and Future Prospects

Despite their successes, cut wire factories face challenges, including fluctuating raw material costs and competition from automated systems that promise quicker turnaround times. Adapting to these challenges will require continuous investment in technology and workforce training.

Looking ahead, the cut wire industry is poised for growth, particularly with the rise of green technologies and sustainable materials. The demand for cut wire products in renewable energy sectors, such as solar and wind, presents significant opportunities for factories willing to innovate.

In conclusion, cut wire factories are integral to modern manufacturing, providing essential products that support various industries. As they evolve, these factories will continue to adapt to changing market demands, ensuring their relevance in the global economy.

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024