2 月 . 08, 2025 01:28 Back to list

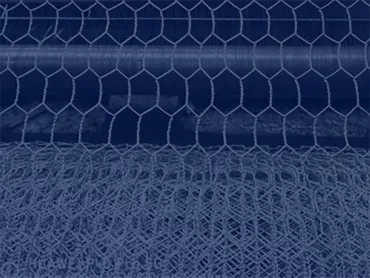

gabion wire specification

Gabion wire specifications have evolved as an essential component in a myriad of construction projects, ranging from infrastructure development to landscaping. As an expert with years of experience in environmental engineering and sustainable construction practices, I have witnessed firsthand the transformative role these specifications play in ensuring both functionality and durability. However, navigating the various specifications to find exactly what suits your project requires careful consideration and expertise.

Tensile strength is another vital specification, one that varies depending on the application. For erosion control along riverbanks, where constant water pressure and debris flow are concerns, higher tensile strength ensures the gabion structures remain intact. Typically, specifications for such uses would demand a tensile strength between 350-550 MPa. Conversely, for decorative purposes or garden walls where the structural demands are less, a lower tensile strength specification may suffice. In determining the appropriate specifications for a project, considering the environmental conditions, expected longevity, and mechanical demands is imperative. Equally, compliance with international standards such as ASTM A975 for galvanized wire or EN10223-3 for hexagonal wire mesh ensures quality and reliability. These standards serve as benchmarks, providing confidence that the material will perform under specified conditions. Installation expertise complements proper material selection, further guaranteeing the durability and functionality of gabion structures. Professional installation ensures that the gabion baskets are correctly filled, preferably with locally sourced stone to blend aesthetics with environmental sustainability. Moreover, securing the gabion with the right wire tying method prevents deformation and preserves the wire’s protective coating, extending the lifespan of the installed structures. In conclusion, gabion wire's specifications play a pivotal role in civil engineering projects, deeply influencing not just the initial performance but also the long-term sustainability and reliability of the structures they form. Engaging with suppliers who provide detailed specification sheets, transparent sourcing information, and adhere to international standards marks a prudent step towards realizing successful and sustainable projects. Ultimately, the integration of expert knowledge, experience, and precision in material selection reflects in the robustness and efficiency of gabion-based solutions across the globe.

Tensile strength is another vital specification, one that varies depending on the application. For erosion control along riverbanks, where constant water pressure and debris flow are concerns, higher tensile strength ensures the gabion structures remain intact. Typically, specifications for such uses would demand a tensile strength between 350-550 MPa. Conversely, for decorative purposes or garden walls where the structural demands are less, a lower tensile strength specification may suffice. In determining the appropriate specifications for a project, considering the environmental conditions, expected longevity, and mechanical demands is imperative. Equally, compliance with international standards such as ASTM A975 for galvanized wire or EN10223-3 for hexagonal wire mesh ensures quality and reliability. These standards serve as benchmarks, providing confidence that the material will perform under specified conditions. Installation expertise complements proper material selection, further guaranteeing the durability and functionality of gabion structures. Professional installation ensures that the gabion baskets are correctly filled, preferably with locally sourced stone to blend aesthetics with environmental sustainability. Moreover, securing the gabion with the right wire tying method prevents deformation and preserves the wire’s protective coating, extending the lifespan of the installed structures. In conclusion, gabion wire's specifications play a pivotal role in civil engineering projects, deeply influencing not just the initial performance but also the long-term sustainability and reliability of the structures they form. Engaging with suppliers who provide detailed specification sheets, transparent sourcing information, and adhere to international standards marks a prudent step towards realizing successful and sustainable projects. Ultimately, the integration of expert knowledge, experience, and precision in material selection reflects in the robustness and efficiency of gabion-based solutions across the globe.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024