2 月 . 13, 2025 04:16 Back to list

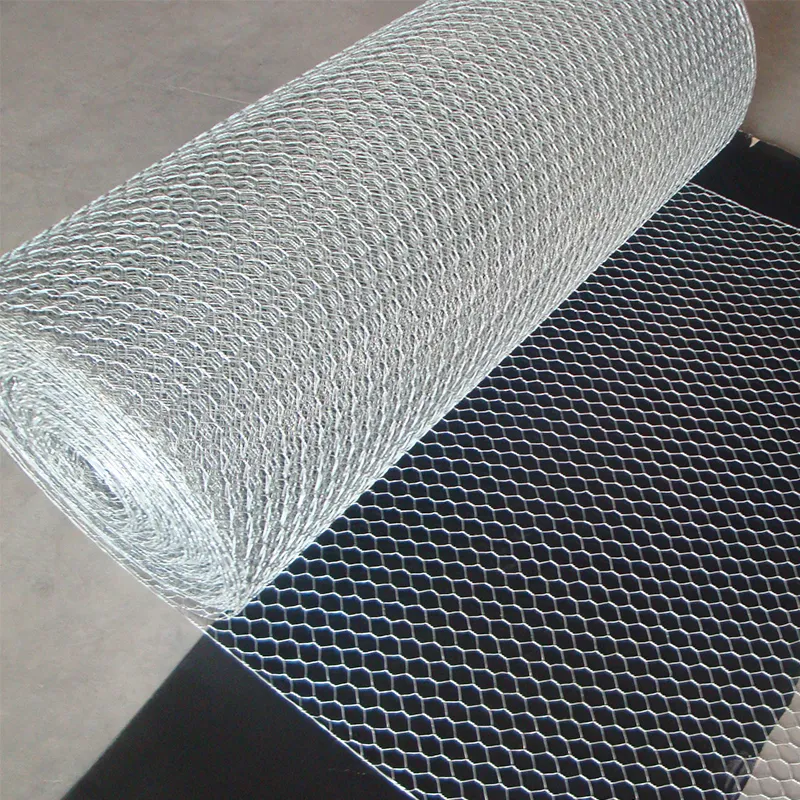

Galvanized Welded Wire Mesh

Galvanised reinforcing mesh is an essential component in modern construction, offering unparalleled strength, durability, and versatility. As building projects grow increasingly complex, the demand for materials that ensure structural integrity has never been higher. Galvanised reinforcing mesh, with its protective coating and robust framework, stands out as a top choice for both residential and commercial construction.

One unique advantage of galvanised reinforcing mesh is its cost-effectiveness over time. While the initial investment might be slightly higher than alternative materials, the long-term savings are considerable. Reduced maintenance requirements and extended lifespan contribute to lower overall costs. Additionally, its ease of installation helps minimize labor expenses, making it an economically smart choice for both small and large-scale projects. For those in the construction industry, understanding the nuances of galvanised reinforcing mesh can lead to better project outcomes. By leveraging its strengths, professionals can deliver projects that not only meet but exceed client expectations. Architects appreciate its aesthetic compatibility with modern designs, while civil engineers value its contribution to structural coherence and integrity. Furthermore, environmentally conscious builders will find galvanised reinforcing mesh aligns well with sustainable construction practices. The durability of the mesh reduces the need for frequent repairs or replacements, thereby conserving resources and minimizing waste. Zinc, the key element in galvanisation, is recyclable, enhancing the eco-friendliness of this material choice. The future of galvanised reinforcing mesh looks promising, with ongoing innovations aimed at enhancing its performance. Researchers are exploring new coatings and advanced galvanisation techniques to further improve corrosion resistance. As technology advances, the integration of smart sensors within the mesh for real-time monitoring and maintenance forecasting might become a reality, offering unprecedented utility and extending the capabilities of current infrastructure solutions. Choosing galvanised reinforcing mesh means choosing a material with a solid foundation of trust, proven performance, and wide-ranging applicability. For projects that demand reliability and strength, reinforced with the assurance of expert endorsements and a legacy of successful implementation, this material is an optimal choice for ensuring structural excellence.

One unique advantage of galvanised reinforcing mesh is its cost-effectiveness over time. While the initial investment might be slightly higher than alternative materials, the long-term savings are considerable. Reduced maintenance requirements and extended lifespan contribute to lower overall costs. Additionally, its ease of installation helps minimize labor expenses, making it an economically smart choice for both small and large-scale projects. For those in the construction industry, understanding the nuances of galvanised reinforcing mesh can lead to better project outcomes. By leveraging its strengths, professionals can deliver projects that not only meet but exceed client expectations. Architects appreciate its aesthetic compatibility with modern designs, while civil engineers value its contribution to structural coherence and integrity. Furthermore, environmentally conscious builders will find galvanised reinforcing mesh aligns well with sustainable construction practices. The durability of the mesh reduces the need for frequent repairs or replacements, thereby conserving resources and minimizing waste. Zinc, the key element in galvanisation, is recyclable, enhancing the eco-friendliness of this material choice. The future of galvanised reinforcing mesh looks promising, with ongoing innovations aimed at enhancing its performance. Researchers are exploring new coatings and advanced galvanisation techniques to further improve corrosion resistance. As technology advances, the integration of smart sensors within the mesh for real-time monitoring and maintenance forecasting might become a reality, offering unprecedented utility and extending the capabilities of current infrastructure solutions. Choosing galvanised reinforcing mesh means choosing a material with a solid foundation of trust, proven performance, and wide-ranging applicability. For projects that demand reliability and strength, reinforced with the assurance of expert endorsements and a legacy of successful implementation, this material is an optimal choice for ensuring structural excellence.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024