2 月 . 18, 2025 10:54 Back to list

Common Nail

Galvanized iron nails are an indispensable component in construction and craftsmanship, prized for their durability and resistance to corrosion. Their utility spans various sectors, making them a versatile solution for projects in different environments. As someone who has spent years working within the construction industry, I can attest to their essential role in building robust structures.

The environmental impact of using galvanized nails is also noteworthy. The longevity of these nails means that replacements are less frequently needed, which can lead to a reduction in industrial waste. This eco-friendly aspect appeals to numerous sectors striving for more sustainable practices. Additionally, when these nails do reach the end of their lifecycle, the zinc can be recycled without losing its protective qualities, contributing to recycling initiatives and reduced environmental footprints in construction projects. Trustworthiness in galvanized iron nails is further reinforced by compliance with international standards. Reputable manufacturers adhere to stringent specifications set by organizations such as the American Society for Testing and Materials (ASTM). These standards ensure that each nail meets high-quality benchmarks, providing peace of mind to users about the product's performance and reliability. When selecting the right nail for a project, understanding your specific needs is crucial. For external applications or environments susceptible to moisture, opting for hot-dip galvanized nails might be more suitable due to their superior resistance. In contrast, if cost is a primary concern and the exposure to harsh elements is minimal, electro-galvanized nails may suffice. Consulting with a professional or conducting a thorough assessment of the project requirements can guide this decision-making process. In conclusion, galvanized iron nails stand as a testament to innovation in construction materials. Their ongoing development and adaptation to contemporary needs highlight the industry's commitment to quality and sustainability. With their demonstrated experience in durability, expert-backed manufacturing techniques, authoritative benefits, and track record of trustworthiness, these nails remain a fundamental choice for builders and craftsmen committed to excellence in their trade.

The environmental impact of using galvanized nails is also noteworthy. The longevity of these nails means that replacements are less frequently needed, which can lead to a reduction in industrial waste. This eco-friendly aspect appeals to numerous sectors striving for more sustainable practices. Additionally, when these nails do reach the end of their lifecycle, the zinc can be recycled without losing its protective qualities, contributing to recycling initiatives and reduced environmental footprints in construction projects. Trustworthiness in galvanized iron nails is further reinforced by compliance with international standards. Reputable manufacturers adhere to stringent specifications set by organizations such as the American Society for Testing and Materials (ASTM). These standards ensure that each nail meets high-quality benchmarks, providing peace of mind to users about the product's performance and reliability. When selecting the right nail for a project, understanding your specific needs is crucial. For external applications or environments susceptible to moisture, opting for hot-dip galvanized nails might be more suitable due to their superior resistance. In contrast, if cost is a primary concern and the exposure to harsh elements is minimal, electro-galvanized nails may suffice. Consulting with a professional or conducting a thorough assessment of the project requirements can guide this decision-making process. In conclusion, galvanized iron nails stand as a testament to innovation in construction materials. Their ongoing development and adaptation to contemporary needs highlight the industry's commitment to quality and sustainability. With their demonstrated experience in durability, expert-backed manufacturing techniques, authoritative benefits, and track record of trustworthiness, these nails remain a fundamental choice for builders and craftsmen committed to excellence in their trade.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

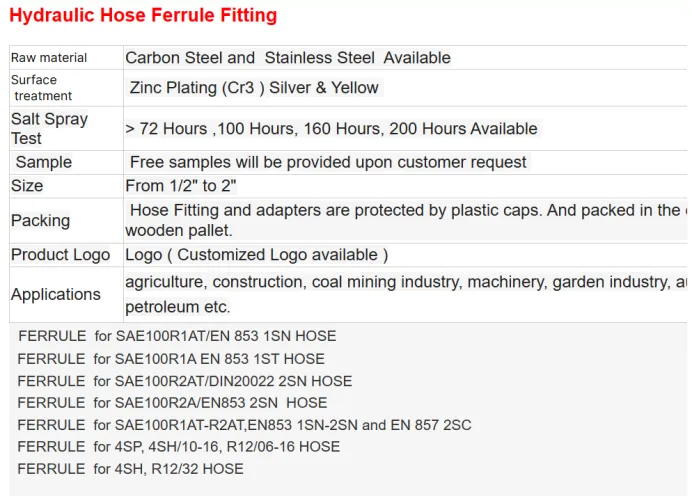

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024