2 月 . 13, 2025 22:01 Back to list

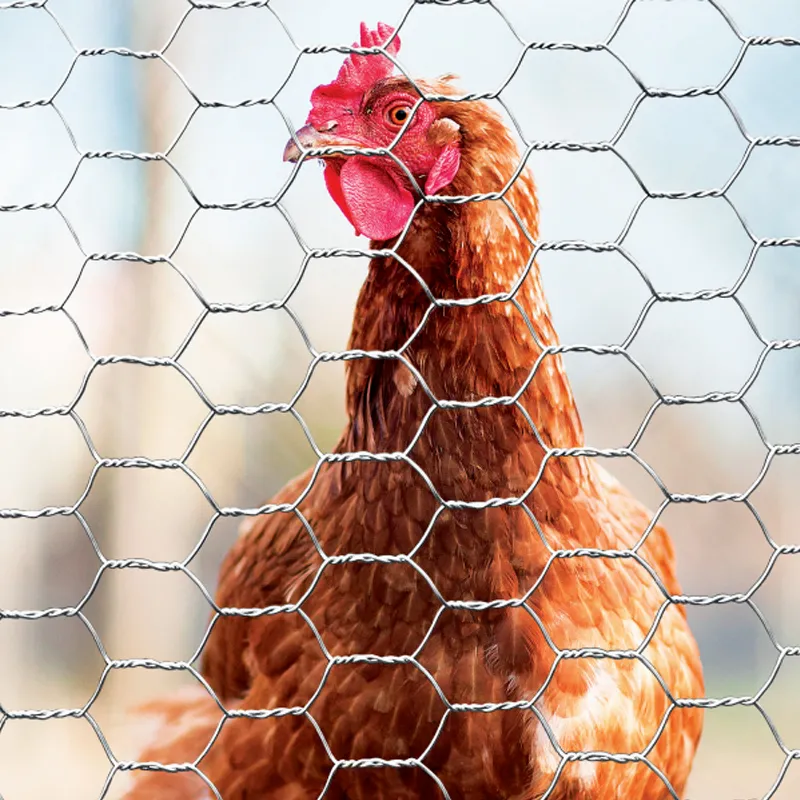

galvanized steel mesh sheets

Galvanized steel mesh sheets, with their robust structure and outstanding durability, have become a cornerstone material in various applications, ranging from construction and architecture to mining and agriculture. Their popularity is driven not only by their mechanical strength but also by their exceptional resistance to corrosion. Understanding their uses and advantages can greatly benefit professionals seeking to optimize their projects with materials that promise longevity and reliability.

For projects aiming for sustainability, the choice of materials is pivotal. Galvanized steel mesh sheets stand out due to their recyclability. At the end of their life cycle, these sheets can be recycled, minimizing environmental impact—a factor increasingly prioritized in modern construction and manufacturing sectors. From a professional development and expertise perspective, understanding the manufacturing process of galvanized steel mesh sheets can provide additional insights into their advantages. The galvanization process involves dipping steel into molten zinc, effectively bonding the two metals. This technique ensures that even if the mesh is cut or damaged, the zinc will act as a sacrificial layer, continuing to protect the underlying steel from rust. This process underlines the expertise and technology behind creating a product that is as resilient as it is versatile. Authoritative sources in the metallurgy and construction industries highlight the unmatched benefits of choosing galvanized steel mesh. Studies and reports frequently cite their cost-effectiveness over time. While the initial investment may be higher than untreated steel alternatives, the reduced maintenance costs and extended lifespan quite often result in overall savings. Trust in galvanized steel mesh sheets is built upon decades of proven performance and rigorous testing standards. Trustworthiness in material choice is enhanced by certification from standards organizations ensuring that these products meet international requirements for safety and durability. Knowing that one's project materials are certified provides peace of mind to engineers and project managers alike, ensuring that their projects won't fall short due to subpar materials. Ultimately, for businesses and professionals integrating galvanized steel mesh sheets into their projects, the key takeaway is a harmonious blend of aesthetics, longevity, and cost-effectiveness. This combination not only meets the functional needs of diverse applications but also aligns with modern demands for sustainable and responsible material usage. These qualities synergize into a product that promises reliable performance, fostering trust, and building a stellar reputation in the industries that depend on these robust components.

For projects aiming for sustainability, the choice of materials is pivotal. Galvanized steel mesh sheets stand out due to their recyclability. At the end of their life cycle, these sheets can be recycled, minimizing environmental impact—a factor increasingly prioritized in modern construction and manufacturing sectors. From a professional development and expertise perspective, understanding the manufacturing process of galvanized steel mesh sheets can provide additional insights into their advantages. The galvanization process involves dipping steel into molten zinc, effectively bonding the two metals. This technique ensures that even if the mesh is cut or damaged, the zinc will act as a sacrificial layer, continuing to protect the underlying steel from rust. This process underlines the expertise and technology behind creating a product that is as resilient as it is versatile. Authoritative sources in the metallurgy and construction industries highlight the unmatched benefits of choosing galvanized steel mesh. Studies and reports frequently cite their cost-effectiveness over time. While the initial investment may be higher than untreated steel alternatives, the reduced maintenance costs and extended lifespan quite often result in overall savings. Trust in galvanized steel mesh sheets is built upon decades of proven performance and rigorous testing standards. Trustworthiness in material choice is enhanced by certification from standards organizations ensuring that these products meet international requirements for safety and durability. Knowing that one's project materials are certified provides peace of mind to engineers and project managers alike, ensuring that their projects won't fall short due to subpar materials. Ultimately, for businesses and professionals integrating galvanized steel mesh sheets into their projects, the key takeaway is a harmonious blend of aesthetics, longevity, and cost-effectiveness. This combination not only meets the functional needs of diverse applications but also aligns with modern demands for sustainable and responsible material usage. These qualities synergize into a product that promises reliable performance, fostering trust, and building a stellar reputation in the industries that depend on these robust components.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024