2 月 . 13, 2025 00:20 Back to list

galvanized welded wire mesh manufacturers

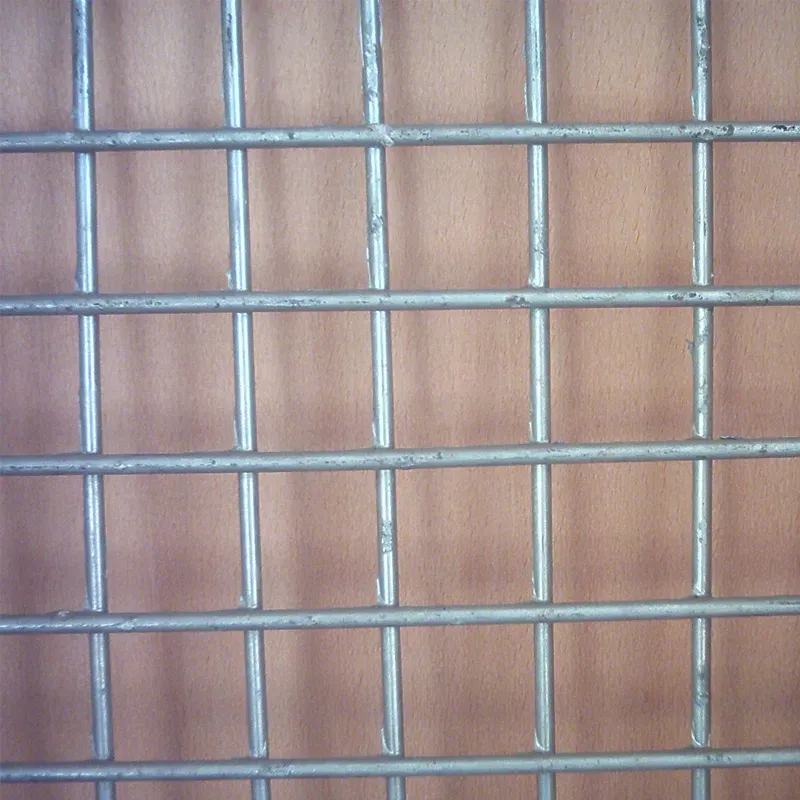

Hot dipped galvanized wire mesh stands as a testament to modern innovation in materials science, celebrated for its robustness and versatility across various industries. Crafted by submerging steel or iron wire mesh in a bath of molten zinc, the hot dipped process creates a durable protective layer that defends against corrosion while enhancing strength. This technique is superior in ensuring long-lasting performance, crucial for applications exposed to harsh environmental conditions.

The environmental impact of hot dipped galvanized wire mesh also deserves mention. The galvanization process is conducted with sustainability in mind. Since zinc is recyclable, the environmental footprint of the production process is minimized. Moreover, the longevity of the material reduces the need for frequent replacements, further cutting down on resource usage and waste generation. From a consumer perspective, one cannot overlook the aesthetic uses of hot dipped galvanized wire mesh. Its sleek, uniform appearance has made it a favorite in modern architecture and design. The durability coupled with visual appeal allows architects and designers to merge functionality with style, offering bespoke solutions for both interior and exterior applications. It can often be found in contemporary art installations, stylish home décor elements like custom shelving, or even ornamental garden features. Professionals and hobbyists alike often encounter challenges when selecting the right mesh specifications to fit their needs. Considering factors like wire diameter, mesh size, and sheet dimensions plays a critical role in ensuring optimal performance for specific tasks. Choosing the appropriate coating thickness further tailors the mesh to the environmental challenges it will face. Consulting with suppliers who have deep expertise and a solid reputation in the field is essential. These experts can provide valuable insights, ensuring that the chosen product meets stringent quality standards and project expectations. Ultimately, the trustworthiness of hot dipped galvanized wire mesh lies in its distinguished track record across sectors and its suitability for various projects that demand strength, durability, and reliability. Investing in this material means prioritizing quality and longevity, factors undeniably crucial for both project success and sustainability in today's fast-paced, demanding world. As technology and materials continue to evolve, hot dipped galvanized wire mesh remains a cornerstone product, offering countless benefits for an expanding array of industrial, agricultural, and consumer applications.

The environmental impact of hot dipped galvanized wire mesh also deserves mention. The galvanization process is conducted with sustainability in mind. Since zinc is recyclable, the environmental footprint of the production process is minimized. Moreover, the longevity of the material reduces the need for frequent replacements, further cutting down on resource usage and waste generation. From a consumer perspective, one cannot overlook the aesthetic uses of hot dipped galvanized wire mesh. Its sleek, uniform appearance has made it a favorite in modern architecture and design. The durability coupled with visual appeal allows architects and designers to merge functionality with style, offering bespoke solutions for both interior and exterior applications. It can often be found in contemporary art installations, stylish home décor elements like custom shelving, or even ornamental garden features. Professionals and hobbyists alike often encounter challenges when selecting the right mesh specifications to fit their needs. Considering factors like wire diameter, mesh size, and sheet dimensions plays a critical role in ensuring optimal performance for specific tasks. Choosing the appropriate coating thickness further tailors the mesh to the environmental challenges it will face. Consulting with suppliers who have deep expertise and a solid reputation in the field is essential. These experts can provide valuable insights, ensuring that the chosen product meets stringent quality standards and project expectations. Ultimately, the trustworthiness of hot dipped galvanized wire mesh lies in its distinguished track record across sectors and its suitability for various projects that demand strength, durability, and reliability. Investing in this material means prioritizing quality and longevity, factors undeniably crucial for both project success and sustainability in today's fast-paced, demanding world. As technology and materials continue to evolve, hot dipped galvanized wire mesh remains a cornerstone product, offering countless benefits for an expanding array of industrial, agricultural, and consumer applications.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024