2 月 . 04, 2025 03:15 Back to list

hydraulic hose connectors fittings

Hydraulic hose connectors and fittings are indispensable components in countless industrial applications, from construction machinery to advanced manufacturing systems. Their role is often underestimated, yet they serve as the backbone for hydraulic systems, ensuring seamless operation and efficiency. When selecting the appropriate hose connectors and fittings, it's crucial to consider several factors to ensure optimal performance and longevity in demanding environments.

Authoritativeness in the sector can be established through engagement with established manufacturers and suppliers who have a track record of producing high-quality hydraulic components. Companies that invest in research and development to enhance the efficiency and longevity of connectors and fittings significantly boost trustworthiness. Certifications from reputable industry bodies further validate the credibility of these components, providing an assurance of quality and compliance with global standards. Trustworthiness is also fostered through transparent business practices and customer support. Manufacturers and suppliers who offer comprehensive warranties and readily available technical support enable users to trust their products, reducing downtime and maintenance costs. Establishing a strong reputation for customer service, including expert advice on installation and troubleshooting, enhances confidence in product performance. Moreover, staying informed about industry trends and technological advancements is crucial for maintaining an authoritative position in this field. Innovations such as quick-connect hydraulic fittings and smart connectors that monitor system performance can revolutionize how hydraulic systems operate, providing even greater efficiency and reliability. In conclusion, hydraulic hose connectors and fittings are critical components that demand careful consideration and selection to maintain system integrity and efficiency. By leveraging experience, expertise, and maintaining a strong commitment to quality and customer satisfaction, businesses can ensure they are equipped with the best solutions. As technology continues to evolve, staying ahead of these trends will be key to optimizing hydraulic systems for future challenges and demands.

Authoritativeness in the sector can be established through engagement with established manufacturers and suppliers who have a track record of producing high-quality hydraulic components. Companies that invest in research and development to enhance the efficiency and longevity of connectors and fittings significantly boost trustworthiness. Certifications from reputable industry bodies further validate the credibility of these components, providing an assurance of quality and compliance with global standards. Trustworthiness is also fostered through transparent business practices and customer support. Manufacturers and suppliers who offer comprehensive warranties and readily available technical support enable users to trust their products, reducing downtime and maintenance costs. Establishing a strong reputation for customer service, including expert advice on installation and troubleshooting, enhances confidence in product performance. Moreover, staying informed about industry trends and technological advancements is crucial for maintaining an authoritative position in this field. Innovations such as quick-connect hydraulic fittings and smart connectors that monitor system performance can revolutionize how hydraulic systems operate, providing even greater efficiency and reliability. In conclusion, hydraulic hose connectors and fittings are critical components that demand careful consideration and selection to maintain system integrity and efficiency. By leveraging experience, expertise, and maintaining a strong commitment to quality and customer satisfaction, businesses can ensure they are equipped with the best solutions. As technology continues to evolve, staying ahead of these trends will be key to optimizing hydraulic systems for future challenges and demands.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

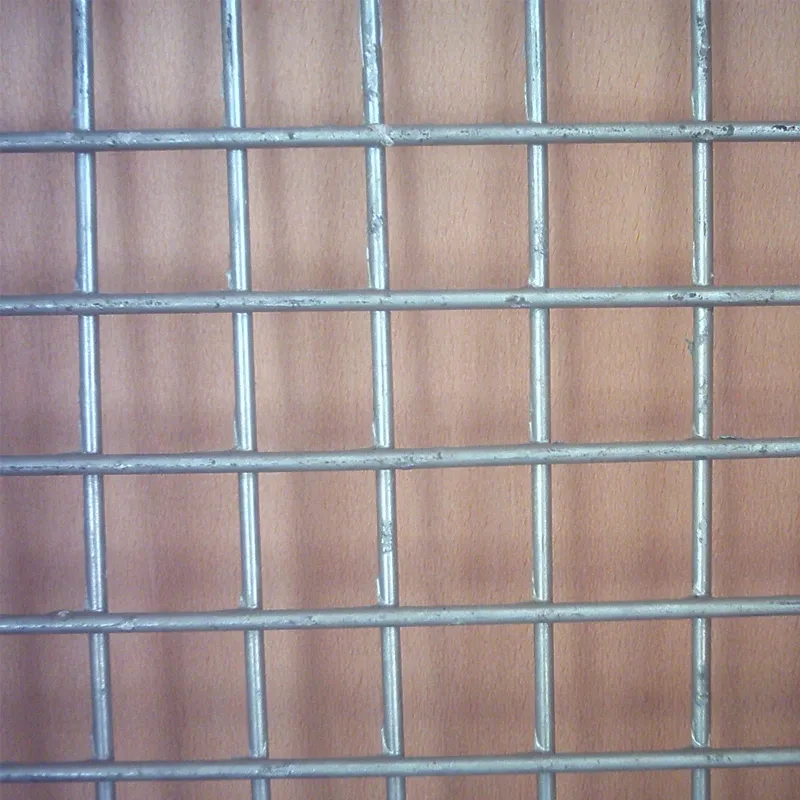

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024