2 月 . 04, 2025 04:01 Back to list

hydraulic hose end fittings

In the world of industrial machinery and hydraulic systems, hydraulic hose end fittings are often overlooked but play a crucial role in ensuring system efficiency, safety, and longevity. The importance of these small yet significant components cannot be overstated, as they provide the critical connection between hoses and other hydraulic system components. This article delves into the key elements to consider when selecting hydraulic hose end fittings, drawing from professional expertise and real-world experience to guide both novices and seasoned professionals.

Trustworthy Installation Practices Proper installation is as critical as choosing the right fitting. Misalignment or overtightening of hose end fittings can lead to leaks, premature wear, and system failures. It's essential to follow manufacturer specifications for torque and alignment to ensure a secure and leak-free connection. Regular inspections and timely replacements of faulty fittings enhance the system's trustworthiness and longevity. Training and adherence to industry best practices are necessary to minimize risks and maintain system integrity. Expert Advice and Manufacturer Reputation When selecting hydraulic hose end fittings, it is prudent to leverage the expertise of seasoned professionals and reputable manufacturers. Manufacturers with a proven track record offer reliable products that meet international standards, ensuring safety and performance. Consulting experienced hydraulic specialists can provide insights into the latest advancements and the most reliable solutions for specific applications. Trust in expert recommendations and the manufacturer's reputation enhances the likelihood of achieving optimal system functionality and safety. Case Study Improving System Performance through Strategic Fitting Selection Consider the case of an industrial equipment manufacturer that experienced frequent hydraulic system failures. By conducting a thorough analysis in collaboration with hydraulic experts, it was determined that incompatible and substandard hose end fittings were the root cause. The team replaced these with high-quality stainless steel fittings suitable for high-pressure applications, effectively eliminating leaks and improving system reliability. This strategic switch not only enhanced performance but also reduced maintenance costs, illustrating the significant impact of proper fitting selection and installation. In conclusion, hydraulic hose end fittings, though small in size, have a substantial impact on hydraulic system performance. Their selection requires careful consideration of material, type, installation, and the reputation of the manufacturer. By prioritizing quality and expert advice, industries can ensure safe, efficient, and reliable hydraulic systems, contributing to overall operational success.

Trustworthy Installation Practices Proper installation is as critical as choosing the right fitting. Misalignment or overtightening of hose end fittings can lead to leaks, premature wear, and system failures. It's essential to follow manufacturer specifications for torque and alignment to ensure a secure and leak-free connection. Regular inspections and timely replacements of faulty fittings enhance the system's trustworthiness and longevity. Training and adherence to industry best practices are necessary to minimize risks and maintain system integrity. Expert Advice and Manufacturer Reputation When selecting hydraulic hose end fittings, it is prudent to leverage the expertise of seasoned professionals and reputable manufacturers. Manufacturers with a proven track record offer reliable products that meet international standards, ensuring safety and performance. Consulting experienced hydraulic specialists can provide insights into the latest advancements and the most reliable solutions for specific applications. Trust in expert recommendations and the manufacturer's reputation enhances the likelihood of achieving optimal system functionality and safety. Case Study Improving System Performance through Strategic Fitting Selection Consider the case of an industrial equipment manufacturer that experienced frequent hydraulic system failures. By conducting a thorough analysis in collaboration with hydraulic experts, it was determined that incompatible and substandard hose end fittings were the root cause. The team replaced these with high-quality stainless steel fittings suitable for high-pressure applications, effectively eliminating leaks and improving system reliability. This strategic switch not only enhanced performance but also reduced maintenance costs, illustrating the significant impact of proper fitting selection and installation. In conclusion, hydraulic hose end fittings, though small in size, have a substantial impact on hydraulic system performance. Their selection requires careful consideration of material, type, installation, and the reputation of the manufacturer. By prioritizing quality and expert advice, industries can ensure safe, efficient, and reliable hydraulic systems, contributing to overall operational success.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

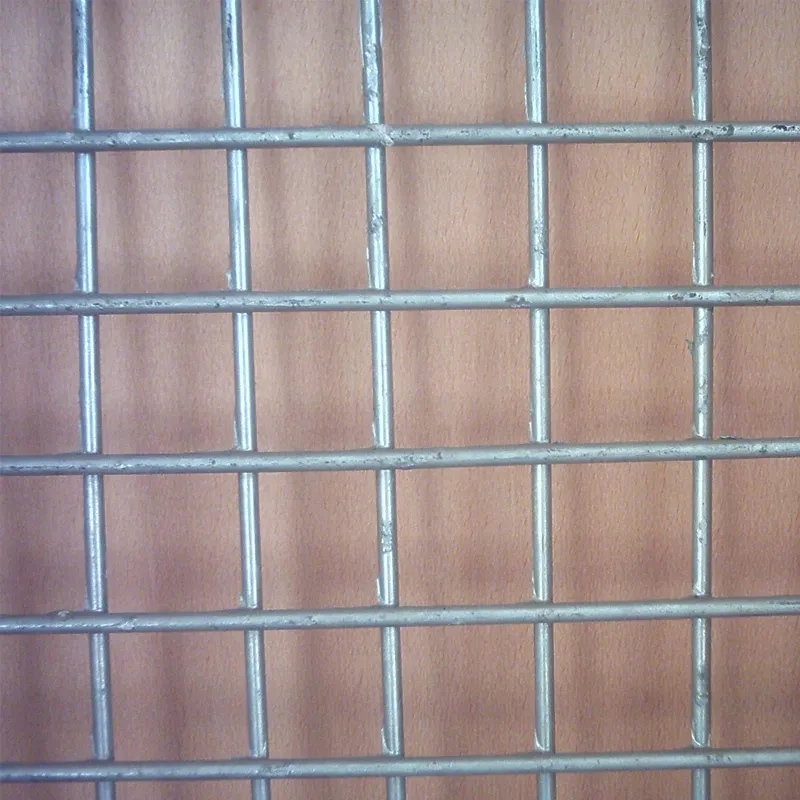

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024