1 月 . 28, 2025 02:07 Back to list

iron nail manufacture

Iron nail manufacturing may appear straightforward, but the reality is a result of an intricate balance between technology, craftsmanship, and industry knowledge. Navigating through this domain requires not only an understanding of the materials but also an acute awareness of the processes involved in transforming raw iron into a fundamental construction staple—the iron nail.

With the physical properties established, coating and finishing processes imbue the nails with additional resistance to environmental adversities such as corrosion and oxidation. Zinc galvanization is a popular choice, creating a protective barrier against moisture. Experts in chemical engineering tailor these coatings to specific user needs, ensuring longevity and dependability in diverse circumstances. Iron nail manufacturers must also navigate the realms of authority and trust. Quality certificates, compliance with international manufacturing standards, and eco-friendly practices build a reputation for trustworthiness in the marketplace. Prominent industry players often participate in and set these standards, reinforcing their position as authoritative figures in the community. Recognition by certifying bodies not only boosts credibility but also fosters consumer confidence. In an era where sustainability is paramount, leading manufacturers are investing in green technologies—striving to reduce carbon footprints and recycle materials wherever possible. This not only aligns with environmental commitments but also serves as a forward-thinking business model that underscores the manufacturer's dedication to sustainable practices. To stand out in the competitive world of iron nail manufacturing, companies must continuously improve and innovate. Regular training for personnel, investment in cutting-edge technology, and a clear understanding of market dynamics cannot be overemphasized. By maintaining a focus on experience, expertise, authoritativeness, and trustworthiness, manufacturers not only preserve their legacy but also pave the way for future growth and innovation.

With the physical properties established, coating and finishing processes imbue the nails with additional resistance to environmental adversities such as corrosion and oxidation. Zinc galvanization is a popular choice, creating a protective barrier against moisture. Experts in chemical engineering tailor these coatings to specific user needs, ensuring longevity and dependability in diverse circumstances. Iron nail manufacturers must also navigate the realms of authority and trust. Quality certificates, compliance with international manufacturing standards, and eco-friendly practices build a reputation for trustworthiness in the marketplace. Prominent industry players often participate in and set these standards, reinforcing their position as authoritative figures in the community. Recognition by certifying bodies not only boosts credibility but also fosters consumer confidence. In an era where sustainability is paramount, leading manufacturers are investing in green technologies—striving to reduce carbon footprints and recycle materials wherever possible. This not only aligns with environmental commitments but also serves as a forward-thinking business model that underscores the manufacturer's dedication to sustainable practices. To stand out in the competitive world of iron nail manufacturing, companies must continuously improve and innovate. Regular training for personnel, investment in cutting-edge technology, and a clear understanding of market dynamics cannot be overemphasized. By maintaining a focus on experience, expertise, authoritativeness, and trustworthiness, manufacturers not only preserve their legacy but also pave the way for future growth and innovation.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

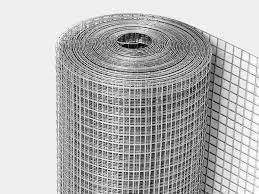

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024