1 月 . 22, 2025 04:53 Back to list

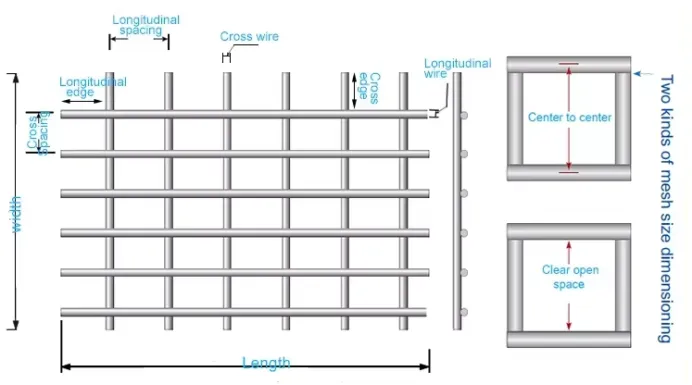

pvc welded mesh panels

PVC welded mesh panels have gained significant traction in a variety of industries due to their outstanding features that offer both functionality and durability. Professionals seeking cost-effective yet robust solutions in construction, agriculture, and even DIY projects find these panels indispensable. Let's delve into the characteristics, applications, and advantages of PVC welded mesh panels, showcasing their superiority and wide-ranging utility.

Despite the technical aspects, the user experience provided by PVC welded mesh panels is equally noteworthy. Installation is relatively straightforward, often requiring only basic tools and expertise, which significantly reduces labor costs and project timelines. This ease of use, coupled with their lightweight nature, means that even large-scale implementations can be achieved with minimal hassle. For DIY enthusiasts, this simplicity opens up a world of possibilities to create everything from custom shelving to decorative elements in home improvement projects. The authority and trustworthiness of PVC welded mesh panels are further reinforced by the credentials of reputable manufacturers who adhere to stringent quality standards. This adherence ensures that each panel delivered maintains uniformity in strength and coating quality. Industry certifications and customer testimonials often back these claims, providing buyers with the confidence that they are investing in a product that not only fulfills promises but outperforms alternatives. Moreover, environmentally conscious consumers will appreciate that PVC welded mesh panels, due to their long lifespan and recyclability, align well with sustainable practices. The reduction in maintenance and replacement needs contributes to a lower carbon footprint, while recycling at the end of their lifecycle ensures that environmental impact is minimized. In conclusion, PVC welded mesh panels are not just a choice; they are the smart choice for those seeking reliability, versatility, and long-term value. Whether for industrial, agricultural, or personal projects, they offer a seamless integration of strength and ease, backed by the assurance of proven performance. Choosing PVC welded mesh panels is an investment in quality and peace of mind, making them an indispensable resource in any professional's toolkit.

Despite the technical aspects, the user experience provided by PVC welded mesh panels is equally noteworthy. Installation is relatively straightforward, often requiring only basic tools and expertise, which significantly reduces labor costs and project timelines. This ease of use, coupled with their lightweight nature, means that even large-scale implementations can be achieved with minimal hassle. For DIY enthusiasts, this simplicity opens up a world of possibilities to create everything from custom shelving to decorative elements in home improvement projects. The authority and trustworthiness of PVC welded mesh panels are further reinforced by the credentials of reputable manufacturers who adhere to stringent quality standards. This adherence ensures that each panel delivered maintains uniformity in strength and coating quality. Industry certifications and customer testimonials often back these claims, providing buyers with the confidence that they are investing in a product that not only fulfills promises but outperforms alternatives. Moreover, environmentally conscious consumers will appreciate that PVC welded mesh panels, due to their long lifespan and recyclability, align well with sustainable practices. The reduction in maintenance and replacement needs contributes to a lower carbon footprint, while recycling at the end of their lifecycle ensures that environmental impact is minimized. In conclusion, PVC welded mesh panels are not just a choice; they are the smart choice for those seeking reliability, versatility, and long-term value. Whether for industrial, agricultural, or personal projects, they offer a seamless integration of strength and ease, backed by the assurance of proven performance. Choosing PVC welded mesh panels is an investment in quality and peace of mind, making them an indispensable resource in any professional's toolkit.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024