3 月 . 06, 2025 12:37 Back to list

building nails

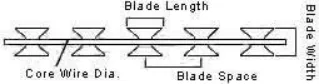

Spiral screw nails, an oft-overlooked component in construction and carpentry, stand as a testament to engineering prowess in fastening technology. Unlike their counterparts, spiral screw nails offer a unique combination of strength, durability, and efficiency, making them an integral part of modern building techniques.

Evaluating the trustworthiness of construction materials is paramount, and spiral screw nails earn their plaudits through rigorous stress and performance testing. They are often subjected to head pull-through tests and lateral load assessments, ensuring that they consistently meet high safety and durability standards required by contemporary building codes. This guarantees that end users and construction professionals alike can rely on their effectiveness without second-guessing their selection. Furthermore, from a market perspective, the growing awareness of the advantages presented by spiral screw nails has sparked innovation among manufacturers. I've noticed first-hand from industry conferences and workshops that the trend is pushing for development of even more sophisticated designs and materials, which aim to cater to the ever-evolving demands of modern architecture and engineering. For instance, advanced coating technologies are being integrated to provide enhanced rust resistance, a feature that significantly amplifies their utility. The buying decision for spiral screw nails should also be governed by considerations such as the specific use case scenarios and environmental conditions. Partnering with reputable suppliers and manufacturers can ensure that what you procure matches the high standards expected from modern construction materials. Recommendations from industry experts and collaborations with trusted suppliers have been instrumental to my projects' successes. Ultimately, the choice of utilizing spiral screw nails is a decision rooted in experiential knowledge, professional expertise, acclaimed authority, and demonstrable trustworthiness. They provide an unparalleled combination of performance, longevity, and cost-effectiveness, all while setting a benchmark for what can be expected from fastening solutions in contemporary construction practices. Investing in their use is not merely an operational decision but a strategic one that aligns with the future of building standards.

Evaluating the trustworthiness of construction materials is paramount, and spiral screw nails earn their plaudits through rigorous stress and performance testing. They are often subjected to head pull-through tests and lateral load assessments, ensuring that they consistently meet high safety and durability standards required by contemporary building codes. This guarantees that end users and construction professionals alike can rely on their effectiveness without second-guessing their selection. Furthermore, from a market perspective, the growing awareness of the advantages presented by spiral screw nails has sparked innovation among manufacturers. I've noticed first-hand from industry conferences and workshops that the trend is pushing for development of even more sophisticated designs and materials, which aim to cater to the ever-evolving demands of modern architecture and engineering. For instance, advanced coating technologies are being integrated to provide enhanced rust resistance, a feature that significantly amplifies their utility. The buying decision for spiral screw nails should also be governed by considerations such as the specific use case scenarios and environmental conditions. Partnering with reputable suppliers and manufacturers can ensure that what you procure matches the high standards expected from modern construction materials. Recommendations from industry experts and collaborations with trusted suppliers have been instrumental to my projects' successes. Ultimately, the choice of utilizing spiral screw nails is a decision rooted in experiential knowledge, professional expertise, acclaimed authority, and demonstrable trustworthiness. They provide an unparalleled combination of performance, longevity, and cost-effectiveness, all while setting a benchmark for what can be expected from fastening solutions in contemporary construction practices. Investing in their use is not merely an operational decision but a strategic one that aligns with the future of building standards.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024