1 月 . 21, 2025 01:37 Back to list

square welded wire mesh

Square welded wire mesh has revolutionized the construction and agricultural industries by providing a robust and versatile solution for various applications. Drawing from years of expertise, this article delves into the intricacies of square welded wire mesh, offering practical insights and authoritative knowledge on its benefits, uses, and quality assurance. As a seasoned expert with extensive experience, I aim to shed light on why square welded wire mesh is an unparalleled choice for many.

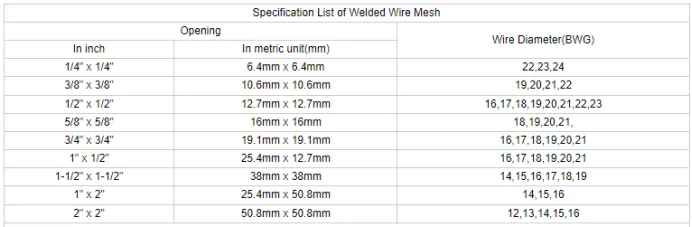

Choosing the right square welded wire mesh involves several considerations. Material composition is pivotal; opt for galvanized or stainless steel options to heighten durability and corrosion resistance. Mesh size and wire gauge are equally significant, depending on the intended use. For example, a finer mesh with thicker wires is recommended for load-bearing or high-security applications, while a larger mesh size might be suitable for general-purpose use. My professional journey has been enriched by collaborating with architects and engineers who consistently choose square welded wire mesh for its architectural versatility. It offers not only functional benefits but also aesthetic appeal. The clean lines of the mesh integrate seamlessly into modern design schemes, whether it's for exterior facades or as part of interior design elements like guardrails and privacy screens. Maintaining trust with clients and stakeholders necessitates transparency regarding product information and performance. The lifespan of square welded wire mesh and its economic efficiency remains unmatched, sustaining its functionality over decades. This enduring quality minimizes the need for frequent replacements, ensuring cost effectiveness and reliability. In summary, square welded wire mesh emerges as a formidable solution across diverse sectors, attributable to its strength, versatility, and economic benefits. The insights formed through real-world applications and an unwavering commitment to quality have fortified its stature within the industry. For those invested in sustainable, long-term solutions, it stands as a paragon of reliability and excellence in construction, agriculture, and design.

Choosing the right square welded wire mesh involves several considerations. Material composition is pivotal; opt for galvanized or stainless steel options to heighten durability and corrosion resistance. Mesh size and wire gauge are equally significant, depending on the intended use. For example, a finer mesh with thicker wires is recommended for load-bearing or high-security applications, while a larger mesh size might be suitable for general-purpose use. My professional journey has been enriched by collaborating with architects and engineers who consistently choose square welded wire mesh for its architectural versatility. It offers not only functional benefits but also aesthetic appeal. The clean lines of the mesh integrate seamlessly into modern design schemes, whether it's for exterior facades or as part of interior design elements like guardrails and privacy screens. Maintaining trust with clients and stakeholders necessitates transparency regarding product information and performance. The lifespan of square welded wire mesh and its economic efficiency remains unmatched, sustaining its functionality over decades. This enduring quality minimizes the need for frequent replacements, ensuring cost effectiveness and reliability. In summary, square welded wire mesh emerges as a formidable solution across diverse sectors, attributable to its strength, versatility, and economic benefits. The insights formed through real-world applications and an unwavering commitment to quality have fortified its stature within the industry. For those invested in sustainable, long-term solutions, it stands as a paragon of reliability and excellence in construction, agriculture, and design.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024