2 月 . 20, 2025 02:12 Back to list

stainless steel common nails

Stainless steel common nails might seem like a small component in construction and woodworking, but their role is pivotal in ensuring the longevity and integrity of a project. While these nails might appear similar to their traditional counterparts at first glance, they are distinguished by their superior properties and performance. This article delves into the unique advantages of stainless steel common nails, emphasizing their unparalleled utility in various applications.

Trustworthiness and reliability are twin pillars of working with stainless steel common nails. Homeowners, architects, and builders alike share peace of mind knowing their projects are secured by hardware that won’t fail weeks, months, or years down the line. This trust translates into fewer callbacks and rework costs for professionals, directly impacting their bottom line. As we advance, sustainability becomes an increasingly vital part of the building industry. Stainless steel, being 100% recyclable, presents an environmentally conscious choice. Using stainless steel nails not only enhances the durability of a project but also aligns with sustainable practices that innovative companies are actively pursuing. Expertise in the domain of construction materials can significantly influence the choice of hardware. Stainless steel nails, with their exemplary balance of performance and durability, showcase why understanding material science is crucial in achieving project success. Educating clients about these benefits can enhance client relationships, showcasing a company's commitment to quality and longevity. In conclusion, stainless steel common nails provide more than just a tool for joining materials; they offer a guarantee of excellence and endurance. Their resistance to environmental degradation and their ability to maintain structural integrity and aesthetic beauty make them indispensable in both small-scale and expansive architectural endeavors. Armed with the knowledge of their benefits, professionals can make informed decisions that enhance the value and reliability of their work, supporting a reputation for quality craftsmanship in an increasingly competitive market.

Trustworthiness and reliability are twin pillars of working with stainless steel common nails. Homeowners, architects, and builders alike share peace of mind knowing their projects are secured by hardware that won’t fail weeks, months, or years down the line. This trust translates into fewer callbacks and rework costs for professionals, directly impacting their bottom line. As we advance, sustainability becomes an increasingly vital part of the building industry. Stainless steel, being 100% recyclable, presents an environmentally conscious choice. Using stainless steel nails not only enhances the durability of a project but also aligns with sustainable practices that innovative companies are actively pursuing. Expertise in the domain of construction materials can significantly influence the choice of hardware. Stainless steel nails, with their exemplary balance of performance and durability, showcase why understanding material science is crucial in achieving project success. Educating clients about these benefits can enhance client relationships, showcasing a company's commitment to quality and longevity. In conclusion, stainless steel common nails provide more than just a tool for joining materials; they offer a guarantee of excellence and endurance. Their resistance to environmental degradation and their ability to maintain structural integrity and aesthetic beauty make them indispensable in both small-scale and expansive architectural endeavors. Armed with the knowledge of their benefits, professionals can make informed decisions that enhance the value and reliability of their work, supporting a reputation for quality craftsmanship in an increasingly competitive market.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

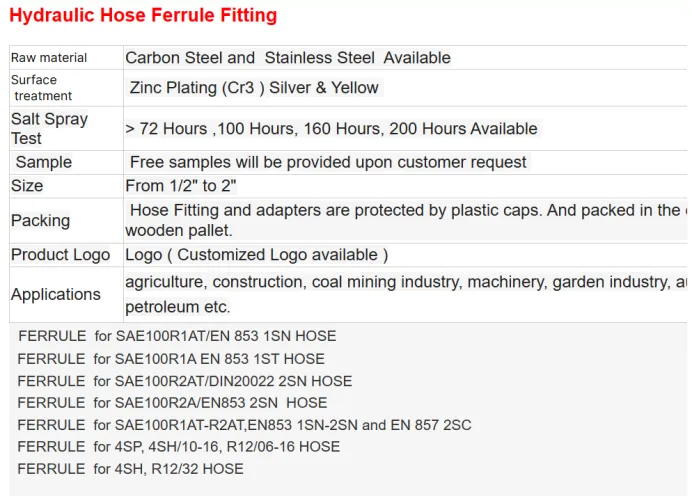

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024