9 月 . 29, 2024 00:28 Back to list

Top Stainless Steel Wire Mesh Manufacturers for Quality Industrial Solutions

The Importance of Stainless Steel Wire Mesh Manufacturers

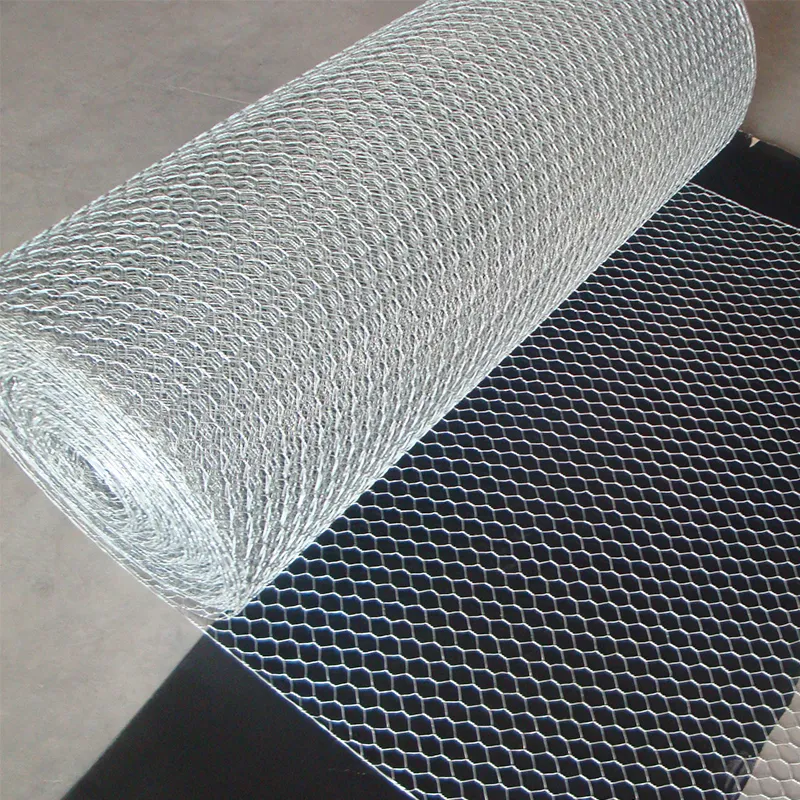

Stainless steel wire mesh has become an indispensable material in various industries due to its exceptional properties such as durability, corrosion resistance, and versatility. With a myriad of applications ranging from construction to food processing, the role of stainless steel wire mesh manufacturers is paramount in ensuring a consistent supply of high-quality products.

The manufacturing process of stainless steel wire mesh involves weaving fine strands of stainless steel into a grid-like pattern. This process can be intricate, requiring precision and expertise to maintain uniformity and strength in the final product. Manufacturers employ various techniques to produce different types of mesh, tailored to distinct industry needs. Such specifications may include varying wire diameters, mesh openings, and surface finishes, each critical for specific applications.

One of the most notable attributes of stainless steel wire mesh is its corrosion resistance. Stainless steel, primarily composed of chromium, forms a protective layer that shields it from environmental factors. This makes wire mesh an ideal choice for applications in harsh environments, such as chemical processing and marine industries, where other materials would quickly degrade. As demand for resilient materials grows, manufacturers must adapt and innovate to meet these evolving challenges.

stainless steel wire mesh manufacturers

In addition to corrosion resistance, stainless steel wire mesh is celebrated for its strength and durability. Manufacturers focus on using high-quality stainless steel grades, such as 304 and 316, which enhance the product's performance. The right choice of material is crucial for applications that involve high pressure or mechanical stress, ensuring safety and reliability.

Another critical aspect is the role of manufacturers in adhering to industry standards and regulations. Different sectors, such as food and pharmaceuticals, require strict compliance with safety and quality standards. Reputable manufacturers invest in quality control measures and certifications to guarantee that their products meet or exceed these expectations. This commitment to quality not only protects end-users but also builds trust in the manufacturers' brand.

Sustainability is also becoming a significant focus within the manufacturing sector. Many stainless steel wire mesh manufacturers are exploring eco-friendly practices, including recycling scrap metal and optimizing production processes to reduce waste. This shift towards sustainability not only benefits the environment but also appeals to an increasingly eco-conscious consumer base.

In conclusion, stainless steel wire mesh manufacturers play a crucial role in providing high-quality, durable, and versatile products that serve a multitude of industries. Their commitment to quality, innovation, and sustainability ensures that they meet the evolving demands of the market while maintaining safety and reliability standards. As industries continue to grow and diversify, the need for reliable stainless steel wire mesh will only increase, solidifying the manufacturers' position in the global supply chain.

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024