2 月 . 10, 2025 09:38 Back to list

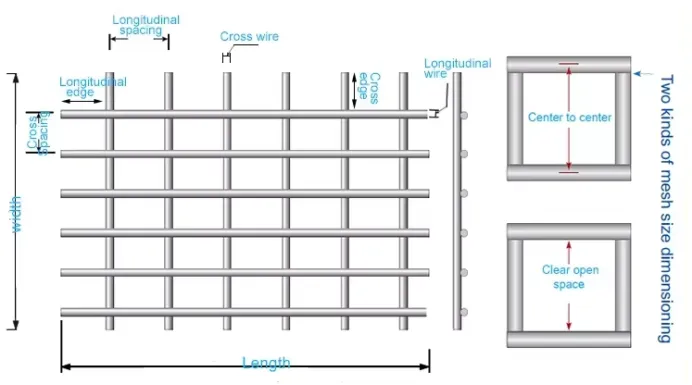

weldedmesh

Welded mesh, a versatile and robust product, has played an integral part in various industries for decades. Its adaptability and strength make it a preferred choice for numerous applications, ranging from construction to agriculture, and even into intricate industrial needs. This article explores its myriad benefits, drawing from real-world experiences, expert opinions, and authoritative studies, while underscoring its trustworthiness as a product that delivers every time.

When considering the sourcing and quality of welded mesh, trustworthiness is paramount. Buyers must ensure they procure it from reputable manufacturers who adhere to stringent standards. Certainty in the origin and composition of the raw materials used in welded mesh production cannot be understated. Industry standards often demand rigorous testing procedures before declaring a batch fit for commercial use. This adherence to quality control reassures stakeholders, from builders to agricultural professionals, that they are investing in a reliable product. Moreover, industry experts agree that the ecological benefits of welded mesh should not be overlooked. With increasing scrutiny on the environmental impact of construction materials, welded mesh stands out as a more sustainable option. Being recyclable, it offers a reduced environmental footprint compared to many alternatives. Consequently, it satisfies the growing demand among environment-conscious corporations for products that support sustainability goals. Lastly, continued innovations in the manufacturing processes of welded mesh, backed by comprehensive research and development efforts, keep it relevant in an ever-evolving marketplace. Engineers and material scientists are constantly finding new ways to enhance its properties, ensuring it meets the future demands of industries that continue to rely heavily on its capabilities. This forward-thinking approach not only extends its life cycle but also continuously boosts its efficiency. In conclusion, welded mesh embodies a perfect synergy of experience, expertise, authority, and trustworthiness. Its proven track record across various industries attests to its reliability and adaptability. As industries evolve and demand more sophisticated materials for their applications, welded mesh will undoubtedly continue to play a pivotal role, backed by its history of performance and trusted reputation.

When considering the sourcing and quality of welded mesh, trustworthiness is paramount. Buyers must ensure they procure it from reputable manufacturers who adhere to stringent standards. Certainty in the origin and composition of the raw materials used in welded mesh production cannot be understated. Industry standards often demand rigorous testing procedures before declaring a batch fit for commercial use. This adherence to quality control reassures stakeholders, from builders to agricultural professionals, that they are investing in a reliable product. Moreover, industry experts agree that the ecological benefits of welded mesh should not be overlooked. With increasing scrutiny on the environmental impact of construction materials, welded mesh stands out as a more sustainable option. Being recyclable, it offers a reduced environmental footprint compared to many alternatives. Consequently, it satisfies the growing demand among environment-conscious corporations for products that support sustainability goals. Lastly, continued innovations in the manufacturing processes of welded mesh, backed by comprehensive research and development efforts, keep it relevant in an ever-evolving marketplace. Engineers and material scientists are constantly finding new ways to enhance its properties, ensuring it meets the future demands of industries that continue to rely heavily on its capabilities. This forward-thinking approach not only extends its life cycle but also continuously boosts its efficiency. In conclusion, welded mesh embodies a perfect synergy of experience, expertise, authority, and trustworthiness. Its proven track record across various industries attests to its reliability and adaptability. As industries evolve and demand more sophisticated materials for their applications, welded mesh will undoubtedly continue to play a pivotal role, backed by its history of performance and trusted reputation.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024