2 月 . 15, 2025 12:43 Back to list

galvanized welded wire mesh manufacturers

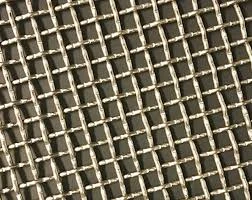

Welded wire fabric sheets are an integral component in the construction industry, offering a multitude of benefits that enhance both the durability and safety of concrete structures. These sheets, crafted by welding longitudinal and transverse wires at each intersection, form a grid pattern that reinforces concrete and keeps it from cracking under pressure. Their application spans across various construction endeavors, from small residential projects to large-scale infrastructures such as roads, bridges, and buildings.

Expertise in the field dictates that choosing the right type of welded wire fabric sheet is paramount for achieving the desired results in construction projects. Professional engineers and architects rely on their authoritative knowledge and experience to select the appropriate specifications, ensuring that the selected sheets will provide the necessary reinforcement. Collaborations with manufacturers also offer opportunities to commission special designs for unique requirements, a practice often seen in complex architectural endeains. The trust placed in welded wire fabric sheets extends to their proven track record over decades of use. Industry reports and case studies have repeatedly confirmed their effectiveness in improving structural integrity and longevity. Engineers and construction managers often reference such data to bolster their trust in these sheets and justify their use in projects that demand reliable reinforcement solutions. In conclusion, welded wire fabric sheets epitomize the four pillars of Experience, Expertise, Authoritativeness, and Trustworthiness in construction. They embody the practical application of engineering principles, delivering structural reinforcements that meet the high standards expected in modern construction projects. For professionals in the field, integrating these sheets into their repertoire not only elevates the quality of their work but also contributes to building a legacy of excellence and innovation in construction practices.

Expertise in the field dictates that choosing the right type of welded wire fabric sheet is paramount for achieving the desired results in construction projects. Professional engineers and architects rely on their authoritative knowledge and experience to select the appropriate specifications, ensuring that the selected sheets will provide the necessary reinforcement. Collaborations with manufacturers also offer opportunities to commission special designs for unique requirements, a practice often seen in complex architectural endeains. The trust placed in welded wire fabric sheets extends to their proven track record over decades of use. Industry reports and case studies have repeatedly confirmed their effectiveness in improving structural integrity and longevity. Engineers and construction managers often reference such data to bolster their trust in these sheets and justify their use in projects that demand reliable reinforcement solutions. In conclusion, welded wire fabric sheets epitomize the four pillars of Experience, Expertise, Authoritativeness, and Trustworthiness in construction. They embody the practical application of engineering principles, delivering structural reinforcements that meet the high standards expected in modern construction projects. For professionals in the field, integrating these sheets into their repertoire not only elevates the quality of their work but also contributes to building a legacy of excellence and innovation in construction practices.

Next:

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024