2 月 . 13, 2025 00:55 Back to list

galvanized welded wire mesh manufacturers

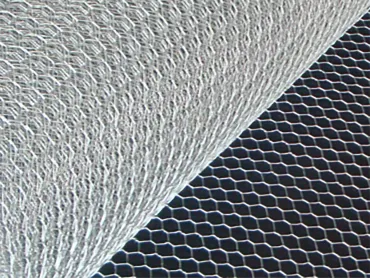

Mesh welded galvanized products have become an indispensable part of multiple industries owing to their exceptional strength, durability, and corrosion resistance. These products are crafted by welding intersecting wires to form a grid-like pattern and subsequently immersed in molten zinc to provide a protective coating. Galvanization enhances the longevity and reliability of these meshes, making them an ideal choice in a wide range of applications including construction, agriculture, and the automotive industry.

Mesh welded galvanized products are also critical in the realm of infrastructure development. They form the backbone of highway guardrails, retaining walls, and safety barriers, providing unparalleled security and resilience. The heightened visibility of galvanized coatings enhances safety by reflecting light, a feature that is especially beneficial in low-light environments such as tunnels or during nighttime. Infrastructure developers trust mesh welded galvanized materials to deliver high performance over long periods, ensuring public safety and reducing the need for frequent maintenance. The process of galvanization — an art as much as it is a science — requires expertise and precision. Only specialists trained in handling zinc coatings can ensure optimal adhesion and uniform coverage, which are critical for maximizing the lifespan and functionality of these meshes. The thickness of the zinc layer determines the level of protection, and experts must carefully balance this aspect to meet specific industry needs while optimizing resource use. Moreover, mesh welded galvanized products have a positive environmental impact. The galvanization process promotes recyclability, and end-of-life galvanized steel can be reprocessed and repurposed without degradation of quality. This sustainable attribute reduces the carbon footprint of industries utilizing mesh welded galvanized products, aligning with global efforts to combat climate change and promote eco-friendly practices. In conclusion, mesh welded galvanized products hold a critical place in modern industry due to their unparalleled performance characteristics. From enhancing the strength of concrete structures to safeguarding agricultural land and enabling durable automotive components, their applications are vast and varied. With expertise guiding every step of their production, these materials offer reliability and peace of mind, establishing themselves as the go-to solution for professionals across diverse sectors. Their protective zinc coating, combined with the enduring strength of welded steel, redefines longevity while ensuring sustainable development and environmental stewardship.

Mesh welded galvanized products are also critical in the realm of infrastructure development. They form the backbone of highway guardrails, retaining walls, and safety barriers, providing unparalleled security and resilience. The heightened visibility of galvanized coatings enhances safety by reflecting light, a feature that is especially beneficial in low-light environments such as tunnels or during nighttime. Infrastructure developers trust mesh welded galvanized materials to deliver high performance over long periods, ensuring public safety and reducing the need for frequent maintenance. The process of galvanization — an art as much as it is a science — requires expertise and precision. Only specialists trained in handling zinc coatings can ensure optimal adhesion and uniform coverage, which are critical for maximizing the lifespan and functionality of these meshes. The thickness of the zinc layer determines the level of protection, and experts must carefully balance this aspect to meet specific industry needs while optimizing resource use. Moreover, mesh welded galvanized products have a positive environmental impact. The galvanization process promotes recyclability, and end-of-life galvanized steel can be reprocessed and repurposed without degradation of quality. This sustainable attribute reduces the carbon footprint of industries utilizing mesh welded galvanized products, aligning with global efforts to combat climate change and promote eco-friendly practices. In conclusion, mesh welded galvanized products hold a critical place in modern industry due to their unparalleled performance characteristics. From enhancing the strength of concrete structures to safeguarding agricultural land and enabling durable automotive components, their applications are vast and varied. With expertise guiding every step of their production, these materials offer reliability and peace of mind, establishing themselves as the go-to solution for professionals across diverse sectors. Their protective zinc coating, combined with the enduring strength of welded steel, redefines longevity while ensuring sustainable development and environmental stewardship.

Latest news

-

Secure Your Roof with Quality Roofing Nails

NewsNov.04,2024

-

Secure Your Property with Quality Field Fencing

NewsNov.04,2024

-

Enhance Your Space with Quality Mesh Fencing

NewsNov.04,2024

-

Discover the Versatility of Iron Wire for Your Projects

NewsNov.04,2024

-

Discover the Versatility of Common Nails for Your Projects

NewsNov.04,2024

-

Discover Quality Hydraulic Fittings for Your Applications

NewsNov.04,2024